In the fresh produce packaging sector, production continuity is an absolute necessity: When a line is automated, the entire process must not stop – or must stop as little as possible. Every machine stoppage, every interruption, and every manual intervention has a direct impact on line efficiency, work organisation, and the reliability of production planning.

© REV Packaging (main)

© REV Packaging (main)

"By listening to our customers," explains Fabrizio Fiumana, President of REV Packaging Solutions, "we realised how crucial this requirement is. This is why Puma 4th Generation was born: the evolution of an already proven machine, redesigned to ensure an even smoother and more consistent production flow. Working fast is not enough – continuity is what really matters. Every stoppage affects the entire organisation."

© REV Packaging (main)

© REV Packaging (main)

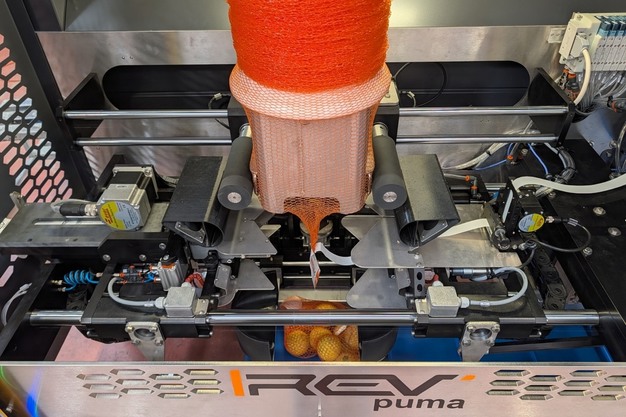

Puma 4th Generation has been designed with a clear objective: To keep production moving by minimising the causes of downtime. Daily operations that would normally require a machine stop can now be carried out without interrupting the production cycle, allowing the line to run in a more regular and predictable way. Tube changes take place without stopping the machine; the cooling water and the handle can be replenished from the outside; and the machine has no doors, being instead equipped with safety barriers, ensuring even faster access.

"We worked to eliminate all those micro-interruptions that, when added up, make the difference at the end of a shift," Fiumana points out. "The result is a more stable production over time, with fewer restarts and greater overall reliability. With over 35 packages per minute, Puma does not aim only at peak speed, but at delivering consistent performance throughout the entire working day, helping packagers to plan better and reduce inefficiencies."

© REV Packaging (main)

© REV Packaging (main)

Great attention has also been paid to the operator experience. The machine has been designed to simplify human-machine interaction.

"With Puma," Fiumana concludes, "production never stops. To discover Puma live, meet us at Fruit Logistica, Hall 2.1, Stand B-23."

© REV Packaging (main)For more information:

© REV Packaging (main)For more information:

REV Packaging Solutions S.r.l.

Tel: +39 0547 384435

Email: [email protected]

www.revsrl.com