It sounds almost like science fiction. But it'll be on the market this year. A scanner that not only analyzes fruit and vegetables' internal quality. It also predicts how long they'll keep. "We're a spin-off from a larger company. It's been developing these kinds of sensors for decades," begins Marco Snikkers, CEO of the Dutch company, OneThird.

"We're redeveloping this specifically for the fruit and vegetable market. And then combining it with the database we're building. That's to offer something meaningful to not only growers and distributors. But retailers and ultimately consumers too. For now, though, the scanner's a B2B product. The system's unique. It can predict products' shelf life. Based on that, users can decide what to do with the batch."

Dynamic codes

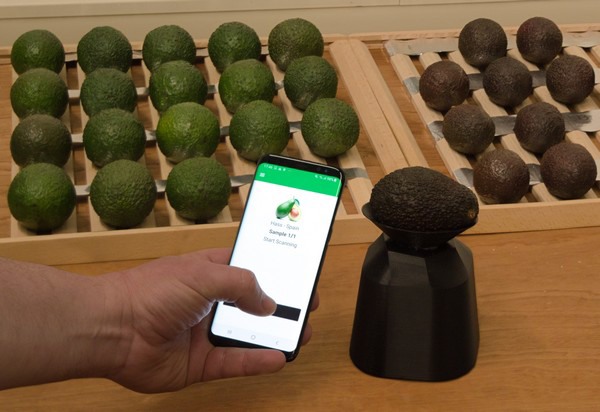

Currently, day codes are affixed to fresh produce. These indicate its estimated shelf life. For example, P6 means the product should be eaten within six days of being harvested. However, this is a static, conservative average. OneThird combines all the product-specific information. It then adds the internal analysis. Here, the inside of the fruit or vegetable is scanned and adequately analyzed—all in less than a second.

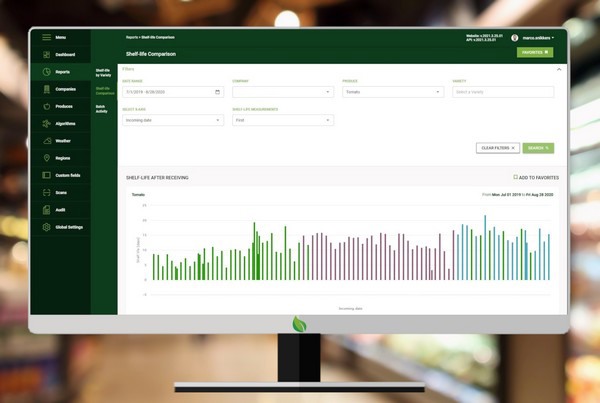

That results in an accurate shelf life estimation. It can be used to adjust the code. "Products' shelf lives vary tremendously. Retailers now use a fixed procedure based on the day code. They sometimes discard fruit that could keep for two more days. They can use the scanner to rescan products and predict their actual shelf life," continues Marco.

"The item can, therefore, still be sold and consumed. Retailers can also, for instance, give extra discounts on products with short shelf lives. Then you can use dynamic shelf life codes instead of fixed codes. Dynamic code predictions consider more factors. So, everyone in the food chain can take better, faster decisions, based on this code."

Artificial intelligence

The scanner measures a product's internal quality. It then uploads this information to a database. This contains all known algorithms about the product's shelf life. But the scanner is also self-learning. Machine learning means the algorithms are constantly updated. In the long term, the scanner should also become available for the consumer market as an app. Phone developers are currently already integrating infrared scanners. The shelf life app could then easily be run on a mobile phone.

Cost-saving

OneThird derives its name from the fact that people throw away a third of the world's food. "At the moment, fruit and vegetable companies struggle to determine products' shelf life beforehand. That forces retailers to discard fresh produce worth hundreds of millions of euros. That's at the direct expense of profits. This scanner can determine fruit and vegetables' shelf life more dynamically. That will mean less wastage and more cost savings," Marco concludes.

For more information:  OneThird

OneThird

527 Hengelose Street

7521 AG, Enschede, NL

Tel: +31 (0) 652 557 997

Email: marco@onethird.io

Website: www.onethird.io