Burg Machinery has been producing pumpkin washing and processing lines for more than ten years. "In recent years, we have supplied lines in the Netherlands, but also in Belgium, Portugal, France and Germany," says Arjan de Nood. "We make from small to large processing lines, using the Burg line as a feed section to a sorting machine."

The smaller lines are usually supplied to growers selling of their premises or to smaller growers who supply distributors. "The pumpkins are often harvested in fruit boxes, which makes it extremely suitable for emptying the pumpkins into the water with a Burg tipper," says the seller.

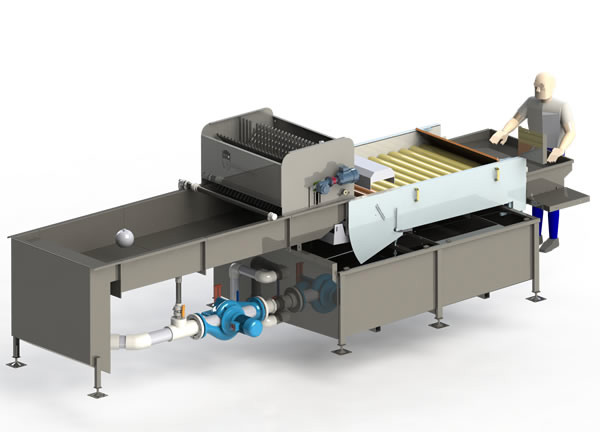

"We also built pump washers that are unloaded directly from the tipper onto a brush unit. Especially for pumpkins grown on sandy soil, it is not always necessary to soak them in the water. On the brush unit they are sprayed with water so that the sand rinses off. In combination with the rotating brushes, the pumpkins are brushed clean."

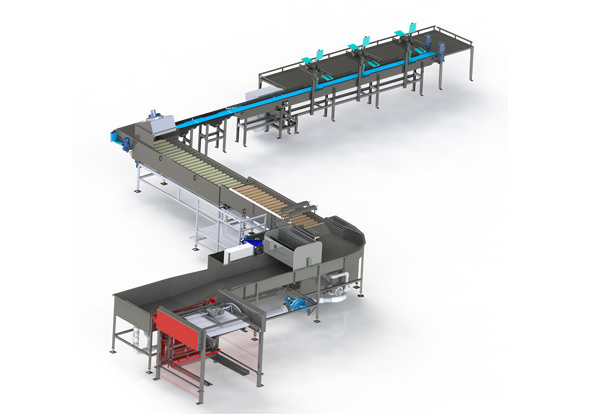

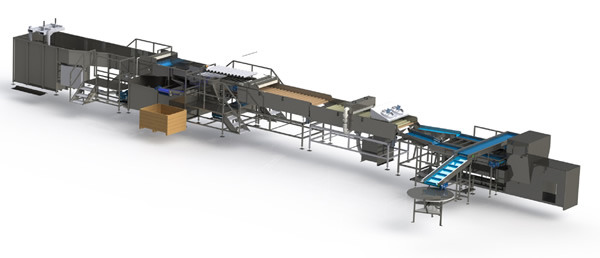

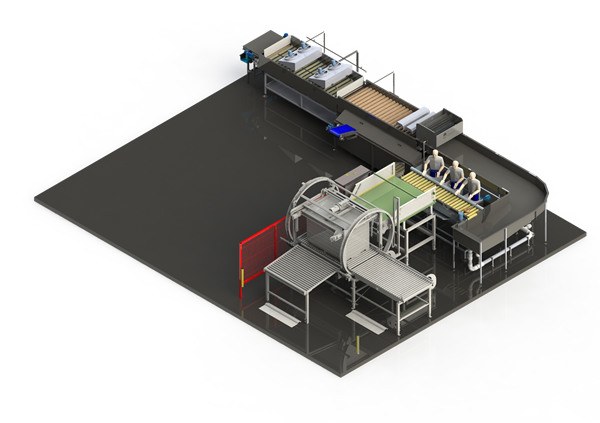

"Larger pumpkin lines are equipped with a fully automatic tipper, which empties the larger agricultural boxes onto a belt in a dosed manner. After going over the sorting table where the stem is cut, the pumpkins go into a water bath. The big advantage of a water bath is the buffer and soaking time of in particular, pumpkins that have stood on heavier clay soil," Arjan explains. "A second possibility is that the full boxes are completely submerged in a large tank. Thus, the pumpkins automatically float out of the box and flow in a dosed manner to the outlet of the water channel. Here a first selection takes place and the stem is cut."

"After the brush unit the pumpkins move to the drying unit. Drying is done by means of a sponge dryer. Optionally we also have built processing lines with air knives, blowers and hot air tunnels. All this depends on how dry the pumpkins have to become," Arjan concludes.

For more information:

Burg Machinery

Arjan de Nood

Weihoek 11

4416 PX Kruiningen

The Netherlands

T: +31 (0) 113 50 1373

adenood@burgmachinery.com

www.burgmachinery.com