Big things are happening at Burg Machinefabriek. This company took a new 5.000 m² building in use in the Dutch village of Kruiningen. That was in 2012. Since then, work has started on the construction of an additional 3.500 m².

Big things are happening at Burg Machinefabriek. This company took a new 5.000 m² building in use in the Dutch village of Kruiningen. That was in 2012. Since then, work has started on the construction of an additional 3.500 m².

"We have been coming up with innovations for the fruit sector since 1954. For the first 30 years in the orchards. Now, in the last 35, we have been developing solutions for packing stations," say Director, Arjan van Burg, and his son, Joan van Burg.

Packing lines around the world are now using Burg Machinefabriek solutions. "We specialize in crate automation and sorting and packaging infeed systems. We ensure complete handling in the packaging warehouse - from the filling and emptying of crates to packaging and palletizing. Automation used to be an aide. Now, processes are becoming increasingly automated. And at high speeds. We have solutions for that."

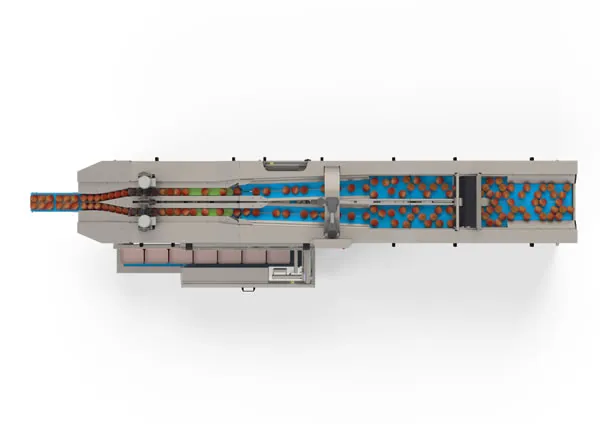

Two of the company's latest innovations will be presented at Fruit Logistica. Burg Machinefabriek will occupy a 112 m² stand at that trade show. The first of these innovations is the high-speed Burg Tray Infeed (BTI). It is a further development of the Burg Flowpacker Infeed system (BFI). The BTI is used for trays. "This line ensures a continuous flow of cardboard trays of apples," explain Arjan and Joan. "This combination of denesting and filling has, up to now, only been done mostly by hand. The BFI has a capacity of more than 60 trays per minute."

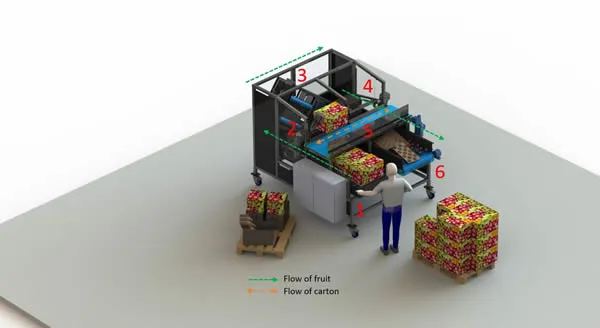

Box loader

The second innovation concerns a box loader for overseas fruit. "This is a compact solution. It loads boxes and crates of different sizes. The crates are rotated 180 degrees in the loader. After that, the boxes are separated from the packaging. That can be done with or without the box's lid. This loader can be integrated into small surface areas. It can be added to existing depalletizing and sorting lines. It can load up to 400 boxed per hour," conclude the Van Burgs.

Burg Machinefabriek's exhibit at Fruit Logistica will be in Hall 4.1, B-14.

For more information:

Arjan van Burg

Burg Machinefabriek

11 Weihoek

4416 PX Kruiningen, NL

Tel: +31 (0) 113 501 373

Fax: +31 (0) 113 502 108

Email: Avanburg@burgmachinery.com

Website: www.burgmachinefabriek.nl