Globally, it is estimated that around 40 per cent of all fruit and vegetables are never consumed. A huge waste of food, water, land, and energy. Often, this waste occurs because somewhere along the chain, the quality of produce does not meet specifications during transport, storage, or in the shop. But what if you knew the exact quality of each piece of fruit or vegetable even before it began its journey? Neolithics is working on that solution.

© Brightland Campus

© Brightland Campus

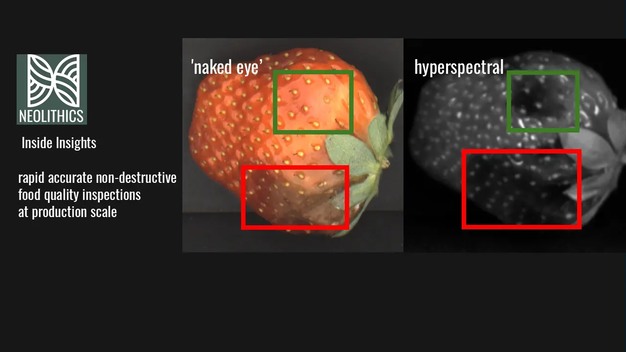

Startup Neolithics, one of the winners of the AI & Robotics in Agriculture Demo Day organised by Brightlands Campus Greenport Venlo and EIT Food, has developed a solution that allows fully automated measurement of the internal and external quality of fruit and vegetables, without damaging the products.

Looking inside fruit and vegetables without cutting them open

While quality checks in the sector are still largely performed manually and based on small samples, Neolithics offers an alternative that is far more accurate and much faster. David Kat, Business Developer at Neolithics, explains: "Currently, for example, only three to five avocados per thousand kilos are checked. To determine quality (subjectively), the avocados are cut open, which is destructive. And the sample size is far too small to draw meaningful conclusions. We fully automate inspections so that every piece of fruit or vegetable can be checked without even being touched."

Neolithics achieves this through a unique combination of hyperspectral light and ordinary RGB video. Hyperspectral light penetrates up to one and a half centimetres deep into the produce, revealing properties such as brix (sugar content), acidity, firmness, and early signs of internal rot even before they become visible on the outside. The RGB camera captures the visual characteristics. Combined, these images provide a complete quality assessment of each product, and this can be applied to the entire stock.

Faster than a human inspection

Whereas a human inspector checks about 300 kilos of blueberries per year, Neolithics' innovative technology inspects 6 kilos per minute in a table-sized device. In other words, it performs more inspections in one hour than a person can do in a year. For avocados on a sorting line, the technology inspects 8 tonnes per hour. This enables complete product streams to be inspected and sorted.

The measurements are analysed immediately using artificial intelligence trained on reference samples of already 20 fruits and vegetables. Each fruit used in the training data was first scanned, then manually cut open and assessed, allowing the AI to learn exactly how internal quality corresponds to what the cameras detect. New models can therefore be built within a single day.

Less waste, better prices

With their solution, Neolithics aims to tackle food waste worldwide. For example, a grower or trader can decide which blueberries are suitable for a long sea voyage to Europe and which are better sold locally. This prevents products from being unnecessarily rejected or discarded upon arrival.

David says: "If you can measure quality at several points in the chain, you can intervene before things go wrong. You prevent waste, but you also improve the price for both farmer and consumer. Because the huge waste in the food system is now included in the prices."

© Brightland Campus

© Brightland Campus

Device from Neolithics

David: "We want to make the food system more efficient, fair, and sustainable. The food chain of the future delivers a more consistent product and a better experience."

Transparent food system

Neolithics is currently collaborating with innovative players in the blueberry and avocado supply chains in South America, the U.S., and the Netherlands. The ambition for the coming years is to track every product from harvest to shopping basket, supported by quality data.

With better data, says Neolithics, growers can harvest more efficiently, logistics partners can optimise cooling, retailers can make smarter purchasing decisions, and consumers can receive better products. David concludes: "We want to make the food system more efficient, fairer, and more sustainable. Not through revolutions, but with proven technology and by building trust step by step. The food chain of the future will deliver a more consistent product and a better experience."

For more information:

Neolithics

[email protected]

https:// www.neolithics.ai/

Source: Brightland Campus