"In the past two years, our focus has shifted to how we, and our clients, can increase returns." That is how Tim Van Win, FAM Stumabo's Benelux Sales Manager, summarizes the impact of current conditions on the potato processing industry.

This Belgian company develops industrial slicers and manufactures precision blades and parts. "The summers were dry, so potato harvests were smaller, making it more important than ever to prevent processing and starch losses. You remove the starch, replacing it with other ingredients like oil. But those things are scarce and expensive. That's why we, and our customers, take a scientific approach to see how we can monitor processing quality and thus increase returns for both French fries and potato chips."

Tim Van Win, FAM Stumabo's Benelux Sales Manager

For instance, the company, along with clients and an engineering team, tests to see how using specific blades, feeding the slicer differently, or using other cutting techniques can help improve results. "That's how we manage to make gains precisely where the true challenges lie," says Tim. To do this, FAM Stumabo considers customers' overall products to find an appropriate solution for each situation. "Freshly grubbed potatoes stretch due to their water content. You use specific blades to get good results with those. Once the tuber has had time to rest in storage, another type of knife is needed for processing. Over the years, we've extensively researched potatoes and know our clients' products extremely well. That's why we endeavor to always offer the optimal solution."

Sustainability

Tim sees that sustainability is another aspect that garners plenty of attention in the potato processing industry. Processing potatoes on an industrial scale is not only efficient but also more sustainable. "Billions of people worldwide buy the various processed products. Those are staggering numbers. If we can achieve one percent less processing waste, we save tons. Not only potatoes but water, too," he declares.

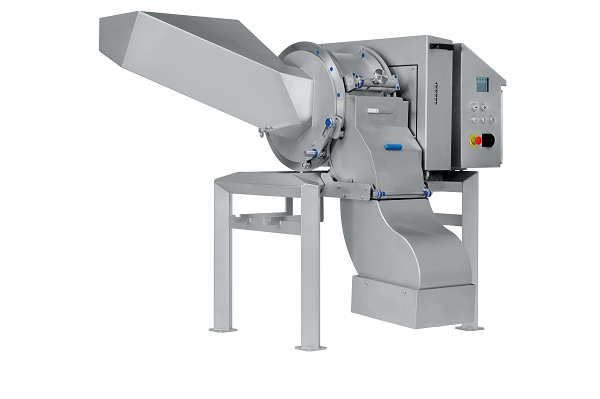

Another aspect is the machines' scale. "Previously, in, say, a chip line, you'd have to divide the incoming product among three machines; now you only need one," Tim notes. He adds that the upscaling requires less energy, but the machines do not consume very much power anyway. Van Wim further states that, for their customers, the total cost of ownership is also an important consideration.

"Our machines are built on five pillars: quality, capacity, simplicity, maintenance, and hygiene. In each of these, we look for ways to reduce costs. These things contribute to a machine's total cost of ownership, and, for us, that's more decisive than energy consumption." That is certainly crucial now that supermarket prices are under pressure. "Food processors, thus, have to be efficient to be competitive," he explains.

Trends

The potato processing sector is subject to trends, something on which FAM Stumabo can capitalize, says Tim. Clients are, for example, always looking for differently cut potato products, especially in the snacking segment. Another potato processing trend that FAM Stumabo sees more and more is battering on potato products, which coats the potatoes, flavoring or making them crispy. This industry is also increasingly processing sweet potatoes. "These are very large, tougher tubers which you have to cater for when feeding the machines. Slicing these requires a different approach."

Increased production in Asia

The company sees that the potato processing sector is doing well. "There's growth in Europe, North and South America, and Asia. In Europe, that's not regarding improving existing processing lines but about new varieties; in Asia, expansion mainly focuses on new construction. There, there's also a trend towards improved potato cultivation; a square meter of potatoes yields up to four times more than a square meter of rice," Tim adds. That, along with that region's population, is leading to the development of regional potato cultivation and processing of potatoes. Which, in turn, means demand for potato products from 'quick service' restaurants is on the rise. "There's massive market potential. FAM Stumabo - through local partnerships - can share its knowledge, so those processors can always achieve the best results, too," he concludes.

![]() Stumabo International

Stumabo International

+32 (0)3 870 70 10

info@stumabo.com

www.stumabo.com

www.fam.be