Sustainability is one of the big issues in the fresh produce sector. In terms of packaging the market has been dominated by the focus on different materials and an overall reduction of materials used to package fruits and vegetables. “We’ve focused highly on the fresh-cut market for the last couple years. Our equipment and design, plus installs have helped these processors scale, while improving overall product quality and reducing operational costs. Now that the most obvious needs have been taken care of, we started to collectively look at what was next,” says Nick Maglio, Director of Marketing at ProEx Food.

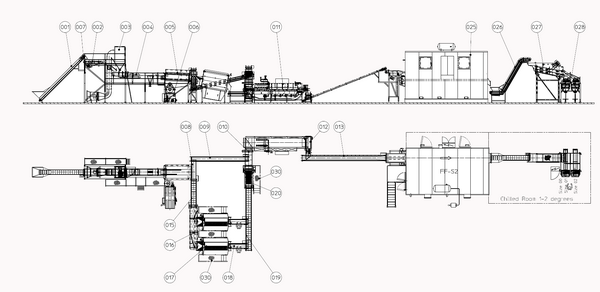

Example of a multi-use line

The company has recently announced their “Gesamtnutzung”-initiative – a need and opportunity to further optimize processing as a whole.

“That isn’t just in terms of energy, equipment hours and/or husks/peels/cores, it’s also about improving overall utilization of raw product. Fortunately, our European production arm has significant experience with IQF / frozen lines. We are now tackling the opportunity to blend operations, bringing in attainable technologies that identify product that are not capable of becoming ‘ideal’ fresh output, but are still highly viable and safe for other product SKUs. These are sent towards alternate processes, such as frozen and/or shelf-stable lines.”

ProEx Food explains how they are continuously improving their shakers, vibratory pans, dewatering systems, graders and similar mechanical equipment to work across more products. They’re also engineering changes to their washers and peelers to accommodate multi-product lines, giving the latter some options to convert between polishing and peeling.

“Early in 2020, we put together several multi-use lines that worked across multiple products, combining downstream into shared mixing and/or packaging”, says Daniel Ghadiri, president and CTO. “We are incorporating similar design principles to split product between various usability criteria.”

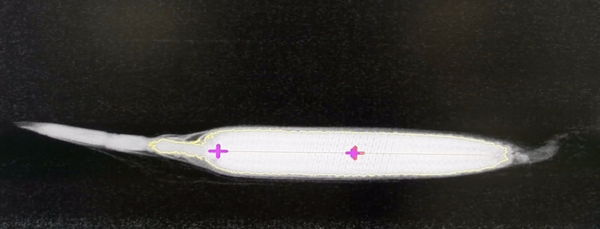

“This, of course, works with our highly efficient fresh (tray packed) sweet corn lines. Our scanning system identifies the cobs that have hidden issues. If a portion of each is still safe and usable, we send it to a different processing path. Could be a cobette, could be kernels, etc. This system further enables us to optimize alignment for top and tail trimming, reducing even more waste. The same principle works on potatoes and other root vegetables, and will soon be available on a wider array of products. Additionally, this method helps eliminate jamming issues on equipment down the line, while reducing your need to stop and sanitize contaminated machinery.

Scanned sweet corn

But why the Gesamtnutzung Initiative name? Maglio explains, “Really, it’s a celebration of our capabilities as well as our staff. We have several team members that come with manufacturing operations experience and a lean operational focus. Plus, Daniel Ghadiri obtained not only his Engineering and Master’s degrees, but also his Ph.d. in Germany and leads our operations there. We’re applying lean and exacting engineering to maximize utilization. And, of course, our US offices are in Milwaukee, which has a strong German heritage. Perfect fit.”

For more information:

Nick Maglio

ProEx Food LLC.

marketing@proexfood.com

www.proexfood.com