"Isolagrande" is one of the largest and most modern greenhouse companies on a national level that was planned in Milan but which was set up in the Vittoria area in Ragusa, Sicily. It truly feels like a Dutch company.

Federico Baraldi

Federico Baraldi

FreshPlaza talked about it with CEO Federico Baraldi who, together with his father Arturo, set up one of the more structured fresh produce production and commercialization companies working on a European level.

"Compared to the Netherlands, though, Sicily is sunnier, which makes a huge difference when it comes to the crops and environmental impact. We specialize in the production of cherry and plum tomatoes and other high-flavor varieties. Our products are able to compete with northern European productions grown under artificial light."

The facility comprises 15 hectares of state-of-the-art high-tech greenhouses plus 55 hectares of greenhouses currently being upgraded. This young company took over a long-standing local company. Ever since the beginning, the objective has been to maintain the positive elements of the old company while improving and making the production segment more efficient (also using the funds granted for R&D).

Part of the fertigation plant

Part of the fertigation plant

Investments were made to improve the greenhouses, a team of specialized agronomists was set up and a computerized control system was put in place to monitor processes and improve the products as well as the economic-managerial and financial efficiency of the company.

"A software controls the entire management of crop processes by monitoring the system from fertigation to the opening and closing of side and top windows. Heating is provided via pipes where hot water flows and which double as rails for forklifts."

With over 200 employees, the company aims at increasing its volumes and improving the work life of its employees.

In the photo above: processing line that can accommodate up to 56 operators when in full operation, used only for 20% of the volumes commercialized by the company (NB: photo take before the Covid emergency)

In the photo above: processing line that can accommodate up to 56 operators when in full operation, used only for 20% of the volumes commercialized by the company (NB: photo take before the Covid emergency)

"It is well known that a pleased worker is a better worker who produces more and is more reliable. This in turn leads to an ethically state-of-the-art product in line with the best practices deriving from the Global GRASP, GlobalGAP, IFS and Leaf certifications. During the first wave of the Covid-19 pandemic, we implemented strict protocols to safeguard our personnel. During the summer months, we kept our security levels high by reducing movements thanks to a brand-new videoconference room."

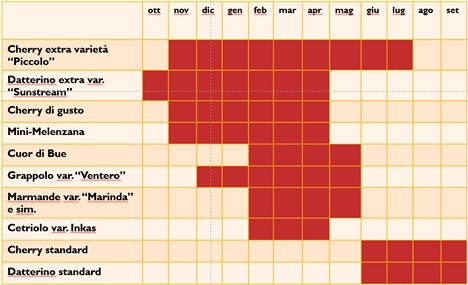

The production calendar

The production calendar

Crops are exclusively soil-less, zero-residue and Nickel-free. A modern heating system inputs CO2 into greenhouses during the day so "plants can strengthen naturally without the need for crop protection products." What is more, accurate checks upon entering the greenhouses prevent the introduction of phytopathogens. The production processes also include useful insects and weekly monitoring to check plant evolution (Crop registration). Traceability is ensured by modern computerized systems.

Productions are of the highest quality, so much so that Isolagrande supplies the largest platforms and supermarket chains in Europe (Great Britain, Germany, Austria, Croatia and Switzerland) and Italy. This is possible as the company is part of OP Valleverde, one of the largest producer organizations in southern Italy.

The company also works with Gandini from Mantua (also a member of OP Valleverde), which is a rare example of collaboration between northern and southern productions. This way, supplies are guaranteed 12 months a year.

Some packaging solutions

Some packaging solutions

The most recent marketing investments "enable Isolagrande to commercialize 20% of its products through the PO and under three brands: Bon Tom (extra category), Isolana (premium category) and Red Green (standard category). The remaining 80% is sold under supermarket brands. The reason is that supermarkets abroad (but in Italy as well) prefer to sell the products under their own brand, especially high-quality ones."

"Prices were negative throughout the summer. Now things have improved slightly and we are expecting the market to settle in early December and then peak before Christmas and until early January. It is difficult to make a forecast with the current global situation, but we are positive."

Contacts:

Isolagrande S.r.l Società Agricola

Sede Legale

Via Achille Zezon 4,

20124 Milano (MI) - Italy

Sede operativa

C.da Alcerito, snc

97019 Vittoria (RG)

Tel.: +39 340 3481913

Email: commerciale@isolagrande.com

Website: www.isolagrande.com