For nearly three decades, Japanese company Astra Inc. has been redefining what's possible in automated fruit peeling. What began as a small innovation on a family farm in Fukushima has grown into a leading force in food processing technology — and the company's newest release, the FAP-3000 industrial pineapple peeler and corer, represents its most ambitious leap yet.

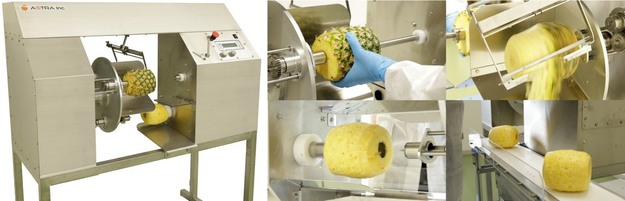

The FAP-3000, officially launched this autumn at the IFPA Global Produce & Floral Show after successful field tests in Japan. According to Astra, it can bring large-scale automation to pineapple processing lines around the world. Combining Astra's established Blade Peel Technology with an all-new industrial build, the machine offers processors higher yields, reduced labour needs, and improved sustainability.

© ASTRA Inc.

© ASTRA Inc.

From local persimmon fields to global innovation

Astra's story is rooted in a simple but powerful idea: making fruit peeling easier and safer. The company was founded nearly 30 years ago in Fukushima, where its first invention — a fully automatic persimmon peeler — was developed to help local farmers save time and reduce physical strain. "Our founder built the first peeler because his mother's hands were injured from peeling persimmons," explains Ryo Takeshita, Sales Manager at Astra. "From the start, our mission has been to reduce physical strain and make people's work easier. Every product we create still carries that same spirit."

Over the years, Astra expanded from persimmons to apples, kiwis, and pineapples, applying its expertise in precise, contour-following blade technology to a growing range of produce. The company's KA-750PM tabletop pineapple peeler proved to be a hit with retailers and small processors, but it left a gap for customers needing higher capacity and integrated coring. "Many customers told us they needed a larger industrial version with a coring function," says Takeshita. "The FAP-3000 was developed directly in response to that demand."

Engineering the FAP-3000

Designing a machine capable of peeling and coring hundreds of pineapples per hour wasn't an easy task. "Pineapples are tough. They vary in size, hardness, and shape more than any other fruit we've handled," Takeshita explains. "Creating a system that adapts automatically while maintaining speed and precision was the hardest part. We completely re-engineered the structure, power, and sensor systems to achieve the stability needed for continuous industrial operation."

© ASTRA Inc.

© ASTRA Inc.

The result is a robust, compact industrial machine measuring 1,25 m wide, 0,55 m deep, and 1,5 m high, weighing around 110 kg. It processes up to 500 pineapples per hour, peeling and coring in one continuous operation. The peeling depth can be adjusted to suit different fruit conditions, and the system is designed for 24/7 production with simple maintenance and easy cleaning.

What sets the FAP-3000 apart is Astra's Blade Peel Technology, which uses precise, contour-tracking blades to remove only the skin, not the valuable flesh beneath. "Unlike machines that grind or cut away the surface, our blades follow each fruit's contour," Takeshita says. "This allows us to peel only the skin while keeping the edible flesh intact, resulting in a very high yield rate of around 53% after coring, compared to 35–40% with conventional machinery."

Boosting yields and reducing labour

The improvements in efficiency are striking, according to Takeshita. He claims one industrial customer in Japan saw a 10% increase in yield and was able to reassign four workers per production line after installing the FAP-3000. "The operation became smoother and more efficient overall," he says. "It's not just faster; it brings stable quality and better profit margins."

In comparative tests, Astra's system achieved yields around 10 percentage points higher than hand-peeling, while cutting labour nearly in half. "Automation helps producers maintain steady quality and efficiency, even when manpower is limited," Takeshita notes. "That's one of the biggest problems we're helping to solve in food processing today."

For pineapple processors, where manual peeling remains labour-intensive and inconsistent, the impact of automation can be transformative. According to Astra, the FAP-3000 ensures uniform quality, reduces food waste, and offers better sustainability by maximising the edible portion of each fruit. "Because the blades remove only the outer skin, we minimize edible loss and boost yield," says Takeshita. "This not only reduces waste but also improves sustainability and overall production cost efficiency."

Ideal for fresh-cut, retail, and catering

While designed for industrial capacity, the FAP-3000 is also built to be compact and user-friendly. It's meant for use in fresh-cut fruit operations, supermarket processing backrooms, and large-scale catering services, such as in-flight meal production. "Even though the FAP-3000 is industrial-grade, anyone can learn to use it safely with minimal training," Takeshita says. "We designed the covers, controls, and cleaning systems with real factory feedback in mind."

Operator safety and simplicity are key design principles. The machine's interface is made to be intuitive, maintenance access is relatively straightforward, and safety guards are integrated throughout its design. According to Takeshita, this reflects Astra's user-centric engineering philosophy.

© ASTRA Inc.

© ASTRA Inc.

Strong global interest

Astra presented the FAP-3000 at several major trade shows, including IFPA, EATS in Chicago, and Gulfood Manufacturing in Dubai. "The feedback has been fantastic," Takeshita says. "Visitors were amazed by how cleanly and efficiently it peels and cores pineapples."

Following these showcases, Astra has seen strong interest from North America, Southeast Asia, and Latin America, where pineapple processing for fresh-cut and juice production is expanding rapidly. The company is also preparing for NSF certification — essential for the U.S. market — and the FAP-3000 already carries the CE mark for European compliance. "Europe is a key region for us due to its strong focus on quality and sustainability," Takeshita adds. "We're also investing in Southeast Asia and Latin America, where demand for pineapple automation is rising quickly."

Beyond pineapples: The future of automated peeling

The launch of the FAP-3000 marks Astra's first major step into the industrial segment, but it won't be the last. The company is already developing new coring technologies for other fruits. "Our next big focus is apple coring," Takeshita reveals. "There's huge demand for automated apple coring, and we're planning to update our apple peeler accordingly."

Automation, labour reduction, and food waste minimization are the main global trends shaping Astra's future R&D roadmap. "Customers everywhere want smarter, safer, and more sustainable ways to process fruit," says Takeshita. "We're expanding our industrial line to other tropical fruits and vegetables, combining high precision with labour-saving technology."

Carrying the spirit of the family farm forward

Despite the high-tech engineering behind the FAP-3000, Astra's heart remains firmly in its founding philosophy, according to Takeshita. "This machine truly represents Astra's mission: turning hard, repetitive work into a smooth and efficient process."

From a simple invention born on a family farm to a world-class automation pioneer, Astra continues to peel back the barriers between people and technology. "When we see factories improving productivity and workers smiling because their job got easier, that's the biggest reward," Takeshita concludes. (JG)

For more information:

Astra Inc

[email protected]

en.e-astra.co.jp