In the greenhouse sector, packaging costs, workflow efficiency, and storage demands are increasingly influencing operational decisions. One area drawing attention is the continued use of pre-folded lids for closing trays of peppers, aubergines, and similar products. While widely used, these lids require considerable storage, involve additional handling, and are more expensive than flat blanks formed directly on the packing line.

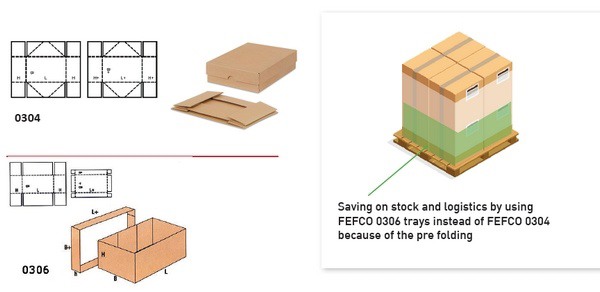

Flat blanks offer several operational advantages. Because they are delivered flat, a higher quantity fits on a single pallet, reducing the number of pallets required and lowering internal logistics pressure. This provides an immediate benefit for facilities with limited storage or those dealing with seasonal peaks in packaging consumption.

© Boix

© Boix

Blanks generally have a lower cost per unit, as they require less handling during production, transport, and storage compared with pre-folded lids. Packers using large volumes of packaging material often record measurable reductions in annual material expenditure when switching to blanks.

Feeding blanks directly into the line and forming them automatically reduces repetitive manual tasks. This lowers labour requirements, which is relevant for packers operating during seasonal peaks when workforce availability is limited.

Because blanks take up less storage and transport volume, the number of transport movements decreases, which can reduce emissions across the supply chain.

© Boix

© Boix

For companies considering the transition to blanks, an automatic forming system is required to shape the lid and place it onto the tray. Such a system must remain compact, reliable, and compatible with tray formats commonly used for fresh produce.

A recently introduced option on the market is a compact hotmelt lid-closing system designed for folding and applying blanks to packing trays. The machine is intended for locations where space is limited and supports production speeds suitable for seasonal peaks. It accommodates a range of common tray types and includes an extended blank-feeding section. Glue application settings can be adjusted easily to optimise sealing across different materials.

The broader trend reflects a move toward packaging solutions that reduce material use, minimise storage demands, and simplify internal logistics. For packers handling peppers, aubergines, and other greenhouse vegetables, shifting from pre-folded lids to blanks offers a route toward lower packaging volumes and more streamlined operations without requiring extensive modification to existing packing lines.

© BoixFor more information:

© BoixFor more information:

Boix Europe

Tel: +31 (0) 313 670 460

Email: [email protected]

www.boix.com