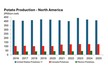

The vast majority of the assortment in Dutch supermarkets often still consists of foreign produce. For typical Dutch products like apples and pears, this has recently received a lot of attention, but for products like sweet potatoes, the perception still often remains that imports are necessary.

However, Dutch product is increasingly gaining a foothold. "It is certainly a challenge, but we can also grow great sweet potatoes here. It is actually too crazy for words to import them from North America, for example, in these times," says Joris van Geel, who founded the company De Zoete Pieper together with his brother Geerd five years ago. "It's a crop with a lot of challenges, but also a lot of potential."

The passion for the agricultural profession is in both brothers' blood. Geerd and Joris' parents have an arable farm, which the brothers grew up on. "About six years ago, we then both got a feeling independently of one another that we wanted to add value to the company. This can be done in several ways, but at the time you saw the sweet potato in the shops more and more and, moreover, people started talking about it more and more. Only, it was often imported from far and wide. Then the thought arose: 'a potato, surely we can do that too'."

"At that time, I was still at the HAS in Den Bosch. There is a graduation course called Top Class Entrepreneurship there. This involves starting your own business as a graduation project. It's a really great opportunity to get stuck into something. That's how we ended up with the sweet potato. Gradually you then learn that it is not related to the potato, for instance," Joris jokes. "We started with 200 square metres and after a visit to Delphy's experimental garden, decided to grow half a hectare to market it as well. Then interest came from larger buyers and that's how the ball got rolling."

"At that time, I was still at the HAS in Den Bosch. There is a graduation course called Top Class Entrepreneurship there. This involves starting your own business as a graduation project. It's a really great opportunity to get stuck into something. That's how we ended up with the sweet potato. Gradually you then learn that it is not related to the potato, for instance," Joris jokes. "We started with 200 square metres and after a visit to Delphy's experimental garden, decided to grow half a hectare to market it as well. Then interest came from larger buyers and that's how the ball got rolling."

Automation increasingly important

Thus, over the years, the brothers' sweet potato acreage has grown to 16 hectares. "This sounds like it went without a hitch, but we had to invent cultivation from A to Z ourselves, so to speak. Of course it was already widely grown abroad, but the climate in the Netherlands requires a completely different way of growing it."

According to Joris, the challenges for the tropical crop lie in two areas. "On the one hand, you have the cultivation. We use biodegradable film over the potato ridges for this. This has several functions; firstly to heat the ridges and secondly, the foil is black, so weeds cannot germinate under the crop.

"Furthermore, automation is also becoming increasingly important. For example, the cuttings of the sweet potato plant come from Portugal. Previously, we had to plant them all by hand. That's a good hundred labour hours per hectare. It's one of the reasons we developed a planting machine together with partners. This is a specialist semi-automatic machine, which almost halves the hours per hectare. We also acquired a new harvester and a machine for laying film. We then adapted these to our needs. Thus, the investments pay for themselves in labour savings. In fact, together with planting material, this accounts for two-thirds of our cultivation costs. We can have little influence on the cost of planting material, but we can reduce personnel costs by continuing to look at automation."

Thus, the investments pay for themselves in labour savings. In fact, together with planting material, this accounts for two-thirds of our cultivation costs. We can have little influence on the cost of planting material, but we can reduce personnel costs by continuing to look at automation."

Right: Joris together with his brother Geerd

Finding balance in harvest timing

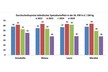

On the other hand, there are also challenges in marketing local sweet potatoes. "Sweet potatoes are sold in size grades," Joris continues. "We mainly focus on the fresh market, but also need the industry. This is because Dutch consumers are used to a smaller potato and these are also in demand. However, sweet potatoes can also grow very large and, moreover, we sort out potatoes with a beauty flaw. However, there is nothing wrong with them, so we take them to the industry. Finding balance in harvest timing is then the 'keyword', because you want as many smaller sizes as possible, but also want to get kilos. Over the years we have paid a lot money learning this, and we continue to do so, but it is never boring."

Creating awareness

As for the season's new crop, the young grower is positive. "It has been a fantastic summer with a lot of sunshine, which is good for such a tropical crop. So in terms of volumes, we are definitely positive. However, the potatoes do seem to have grown a bit bigger, which is not necessarily advantageous for us because smaller sizes, as mentioned, are in demand."

This year too, however, the brothers have seen why automation matters. "The beginning of the growing season was relatively dry. During harvest, it suddenly went from dry to extremely wet very quickly. We used to harvest about an acre a day and I challenge you to find 16 days of good weather in September. So they have to be brought in in a shorter time, which we have been able to achieve through the mechanical harvester."

On the demand side, the popularity of sweet potatoes also continues to grow steadily. "It is increasingly finding its place on Dutch shelves. For us it is important that the demand for Dutch product also grows. However, it is difficult to compete with cheaper foreign product, but we don't have to be the cheapest either. We have something others don't have: a local and sustainable product. People's awareness in these times is growing, but there is still a world to be won. Our customers range from (online) retail to industry, but it is too expensive a product to grow recklessly. That is why we are always looking for buyers, because demand has to keep up with supply."

For more information:

Joris van Geel

De Zoete Pieper

+31 (0)63865571

[email protected]

www.zoetepieper.nl