As long as the coronavirus is in the world, a demand for being able to have as little interaction with food products as possible will exist. One Swedish processing line manufacturer has ensured their machinery can be handled with a small workforce.

The coronavirus has led to a more extreme view on how we’d like to handle our food products. Ruben Larsson, founder of OctoFrost, says they’re now offering complete lines to meet this demand: “Ever since the Covid-19 pandemic, we’ve seen an increase in demand for the ‘no hand touch’ operation of food products. IQF, or Individual Quick Freezing, packed at the source meets customers’ demand of food-safe handling until end-users’ cooking and consumption. To meet this growing demand OctoFrost designs and supplies a number of ‘complete lines’, being the only responsible supplier for the full line.

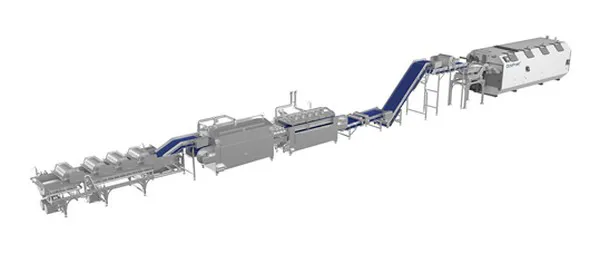

OctoFrost has tried to make its processing line as universal as possible, without the need of a large workforce: “With our OctoFrost IQF Universal Vegetable Line almost all products can be randomly fed to the line and gently spread with a shaker or water flumes; and with a tedder for leafy products like spinach. A complete line designed and supplied by OctoFrost only requires two to three operators, saving labor and cost.” Larsson explains.

“In the OctoFrost Blancher, vegetables are either fully blanched with +73C to 85C water or steam or flash blanched with hot water to kill surface bacteria. This heat treatment is followed by an immediate chilling to maintain products’ natural texture and color. Water temperature in OctoFrost Rainfall Chiller is 1 to 3 degrees Celsius under the critical +6C in home used fridges, which is safe.”

One issue with freezing vegetables is being able to separate them despite the high content of water, says Larsson. “Vegetables usually have high-water content and can stick together during the freezing process. However, the unique bedplate configuration and easy-to-control freezing process in the OctoFrost freezer can guarantee the product is well separated, while maintaining a natural appearance.”

OctoFrost also has processing solutions for delicate vegetables like spinach and asparagus that require gentle handling, Larssson states. “The OctoFrost IQF Spinach Line consists of an OctoFrost IF Blancher, IF Chiller, a Rotating Tedder and an IQF freezer. After the chilling stage, it comes to dewatering, OctoFrost provides a Rotating Tedder to achieve good product separation. The OctoFrost IQF Asparagus Line is completely horizontal, meaning all belts are at the same level, so asparagus only needs to lie static during the processing period. This means there will be no damag, even to long and thin asparagus, because they are transported through the freezer without any drops.”

For more information:

OctoFrost Group

Email: sales@octofrost.com

www.octofrost.com