Argon (Ar) and nitrogen (N2) are the main gases used in modified atmosphere packaging (MAP), and many studies have demonstrated their efficacy in reducing microbial growth and improving the quality retention of fresh produce.

A group of Chinese researchers (Wu et al., 2012) has studied the effects of high-pressure argon and nitrogen on respiration rate, tissue browning and antioxidant power in fresh-cut pineapple.

A group of Chinese researchers (Wu et al., 2012) has studied the effects of high-pressure argon and nitrogen on respiration rate, tissue browning and antioxidant power in fresh-cut pineapple.For the work, the pineapples (Ananas comosus L.) harvested in Hainan (China) and supplied by a local distributor were stored for 24 h at 10±1 °C before minimally processing.

Then, pineapples were peeled, washed in an aqueous solution of 200 µl/L sodium hypochlorite at 4°C for 5 min, cut into 2 cm thick wedges, pressurized, depressurized, packaged and stored in darkness at 4°C for 20 days.

Pressure treatments included six groups:

- Control (Not treated);

- Normal atmospheric-pressure Ar treatment with 99.7% pure Ar (NAP Ar);

- Normal atmospheric-pressure N2 treatment with 99.7% pure N2 (NAP N);

- High-pressure air treatment (HP air; 10 MPa);

- High-pressure Ar treatment (HP Ar; 10 MPa);

- High-pressure N2 treatment (HP N; 10 MPa)

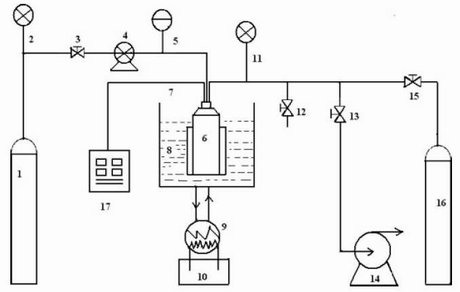

Schematic diagram of high pressure gas-processing equipment. 1. Gas cylinder. 2. Pressure gauge. 3. On-off valve. 4. Plunger pump. 5. Pressure transducer. 6. High-pressure vessel. 7. Thermocouples. 8. Water bath container. 9. Thermostatic bath. 10. Refrigerant compressor. 11. Pressure gauge. 12. Relief valve. 13. On-off valve. 14. Vacuum pump. 15. Vent valve. 16. Exhaust gas cylinder. 17. Display panel.

The samples were analyzed just before packaging and after storage for 2, 5, 8, 11, 14, 17 and 20 days. The analyses consisted in the determination of the respiration rate, ethylene production, tissue browning, antioxidant potential (evaluated by the total phenolic compound content and ascorbic acid content, by DPPH free radical-scavenging assay, by ABTS radical cation decolourisation assay, by FRAP assay), pulp texture and juice leakage.

The results has shown that after 14 days of storage the respiration rate rapidly increased apart from the treatments confirming the results of other scientific studies, according to which the respiration rate of fresh-cut pineapple was significantly influenced by storage temperature and, in general after 12 days of storage at 5°C, the visual signs of microbial spoilage occurred indicating the end of shelf-life.

However, the respiration rate was less in the samples HP Ar and HP N than in the samples untreated, NAP N, NAP Ar, and HP air treated samples.

Also the ethylene production was less in the high-pressure treated samples, especially in HP Ar and HP N samples.

The authors have hypothesized that the inhibitory effect of HP Ar and HP N treatment on respiration rate and ethylene production may be due the gas hydrate formation and residual Ar o N2 in micropores of pineapple wedges, which could limit the activity of intracellular water and enzymes in the fruits, thus slowing down their metabolic processes. Another explanation, which needs of further investigations, could be that the HP Ar and HP N treatments create anaerobic conditions, thus both respiration rate and ethylene production are reduced.

For the same reasons, the pulp browning resulted less in the HP Ar and HP N treated samples than in the untreated samples and in HP air, NAP N and NAP Ar samples.

In regard to the antioxidant power, after 20 days of storage both the total phenolic compound content and ascorbic acid content decreased, even if the least reduction was in HP Ar and HP N samples, and the HP Ar treatment resulted the most effective in limiting the losses.

The total phenolic compound content in control (untreated) wedges and those treated with HP air, HP Ar and HP N before the storage was 454, 420, 439 and 433 mg gallic acid kg-1 FW, respectively, while after 20 days the content decreased up to 362, 353, 443 and 409 mg gallic acid kg-1 FW, respectively. Also the ascorbic acid decreased after 20 days by 52% (HP air), 48% (control), 47% (NAP N), 46% (NAP Ar), 33% (HP N) and 30% (HP Ar).

During storage a 4°C, the HP Ar and HP N treatments had no effects on tissue firmness and juice leakage of fresh-cut pineapples.

The present work has demonstrated that high pressure application with Ar and N2 could be a promising method for preserving the quality not only of fresh-cut pineapple but also of other fruits.

Original study. Wu Z.S, Zhang M., Wang S.J, ‘Effects of high-pressure argon and nitrogen treatments on respiration, browning, and antioxidant potential of minimally processed pineapples during shelf-life’, 2012, Journal of the Science of Food and Agriculture, Issue N. 92, pagg. 2250-2259. Further info: http://www.ncbi.nlm.nih.gov/pubmed/22368048