Besides the use of chemical compounds, the scientific research has shown the efficacy of Modified Atmosphere Packaging (MAP) to slow down quality and safety decay in fresh-cut products. Controlled atmosphere with high concentrations of carbon dioxide (15%) were found effective in maintaining visual quality and reducing microbial growth in fresh-cut melon, but gas effects on firmness and sugar concentrations were varied according to the melon varieties.

Researchers tested 36 gas combinations on four fresh-cut melon varieties, the gas combinations that allowed to preserve the best sensory quality were those based on oxygen ranged between 3% and 6% and carbon dioxide between 6 and 15%.

Studies on MAP involve two topics:

- internal atmosphere composition of package;

- materials used to manufacture packaging films.

The researchers of the University of Foggia (Italy), Conte et al. (2009), conducted a study on fresh-cut "Barattiere" melon (Cucumis melo L.), which is a typical product of Apulia Region, The objective of the work was to assess the suitability of four packaging materials, differing in water vapour and gas barrier properties, to preserve quality and safety in fresh-cut melon during storage period.

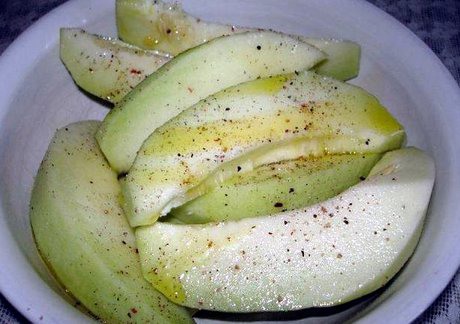

'Barattiere' or 'Carosello' melon; a typical product from Apulia (Italy), a sort of cross between a white melon and a cucumber. It is usually eaten with a sweet or spicy dressing.

For the work, the Barattiere melons were harvested from a commercial agricultural farm "La Pietra" (Monopoli, Bari, Italy), after harvesting the fruits were transported under refrigerated conditions to the laboratory, where they were selected for uniformity, absence of physical defects and colour, then they were washed and sanitized. After cutting, melon slices were dipped for 1 min at room temperature into a solution containing ascorbic acid (1.0%) and calcium chloride (0.2%).

Then, the slices were packaged testing four different films:

- NVT1 film, a lumltilayer co-extruded film based on a blend of biodegradable polyesters, thickness 35µm;

- NTV2 film, a monolayer film based on a blend of biodegradable polyesters, thickness 50µm;

- OPP film, an oriented polypropylene film, thickness 20µm;

- MLF film, , a multilayer film obtained by lamination a nylon film with a polyolefin film, thickness 95µm.

Results showed that film characteristics influenced gas concentration (O2 and CO2) in the package headspace, microbial growth, and mass loss. O2 concentration in the MLF bag headspace was constantely lower (0-5 kPa) than in the other films, on the contrary it was the highest (15-20 kPa) in the OPP bag headspace. The MLF film was the most effective to slow down the microbial growth during storage period.

The high CO2 concentration in the headspace and its technical characteristics allowed to inhibit microbial growth, in fact the Microbiological Acceptability Limit (MAL) > 7 log UFC/g for mesophilic and psychrotrophic bacteria was reached after 14-15 days of storage in fresh-cut melon packaged with MLF film, while MAL was reached after 9-10 days in the fresh-cut melon packaged with the other three films. MLF and OPP films resulted more effective than biodegradable films in limiting the mass loss, which was 2% in the former and varied from 4% to 8% in the latter.

Conclusions

The research has highlighted the possibility to use biodegradable films to preserve fresh-cut products, but their efficacy in preventing phenomena decay is limited to 7-8 days of shelf-life. The authors concluded underling the necessity to continue the research to improve the technical characteristic of biodegradable films, so that they can substitute the commercial film currently used. In addition, the consumers should appreciate the low environmental impact of manufacturing and using these films.

Original work. Conte A., Scrocco C., Brescia I., Del Nobile M.A., "Different packaging strategies for fresh-cut ‘barattiere’ melon cultivar (Cucumis melo L.)", International Journal of Food Science and Technology, 2009, Issue No. 44, pagg. 1422-1428. For more details: http://onlinelibrary.wiley.com/doi/10.1111/j.1365-2621.2009.01973.x/abstract