A multi-product sorter that’s able to work on all sorts of produce, including oblong and irregular shapes. It’s called the Sidewinder. “There is no other machine on the market that can match the throughput of the Sidewinder across the variety of products it can sort,” says Boomer Batchman, CEO of Exeter Engineering in California. The company built and sold its first Sidewinder in 2016 and has since been iterating on the machine and improving both its quality and its capabilities.

Different products

Sidewinder differentiates itself from other sorters in the market because of its multi-product capabilities. Below is a photo of pomelos being sorted. However, the company also has customers running other citrus fruit varieties (grapefruit, oranges, lemons, etc.), bell peppers, tomatoes, melons, onions, cucumbers, potatoes, hard squashes, as well as soft squashes. In addition, it handles oblong and irregularly shaped fruit. “The beauty of the Sidewinder is that it can be configured for a variety of products. It takes about 90 minutes of easy adjustments and testing to start running a different crop through the same sorter with the same high speed and high-quality results.”

Pomelos on Sidewinder.

AI capabilities

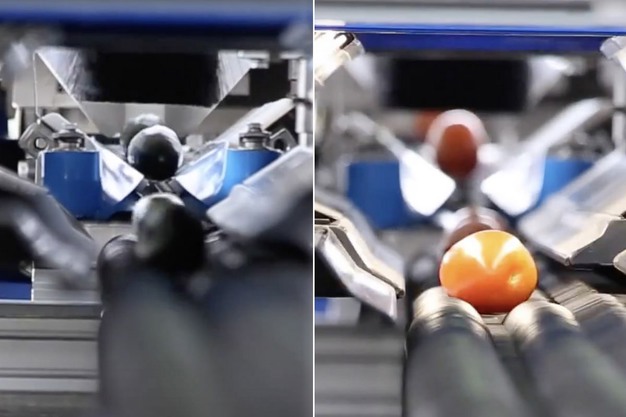

Another differentiator is the machine’s unique presentation system. From the infeed system, the product is placed on a unique carrier system that spins the product 360 degrees as it passes under the camera hood. “That gives our ID Technology system’s imaging array a complete view of each piece of product. We believe that better images yield better, more consistent grading decisions while also reducing returns,” said Batchman. Last year, AI capabilities were launched for bell peppers and cucumbers, for instance, providing a grading accuracy of more than 95 percent. The company is currently working on perfecting its models for zucchini/courgette and pomelos.

Cucumbers and Roma tomatoes, showing camera presentation angle.

Lastly, the Sidewinder is known for being robust. “It is engineered to be easy to operate and easy to maintain.” All of the mechanical components have easy access, and the parts that are subject to wear and tear are all easily and cheaply replaceable. “There is nothing too delicate about the Sidewinder. It’s made to stand up to lots and lots of use, with 304 steel throughout and industry-standard electrics, motors, etc.”

8-lane Sidewinder installed.

8-lane Sidewinder installed.

Speed

The speed of Sidewinder depends on the product as well as the configuration of the machine. “Some of our customers are packing bell peppers on a 10-lane set-up with 30 drops that are consistently seeing a throughput of 66,000 lbs/20,000 kg. per hour. However, for smaller machines like a 4-lane machine running on cucumbers, customers report they are running about 38,000 pieces per hour.” Depending on what type of product is running, what defects are being graded for, and how many drops are being used, speeds can go higher or slower.

Bell pepper on Sidewinder presentation system.

Modular construction

While the Sidewinder is already very versatile, Exeter is redesigning the sorter to make it even more versatile. “It will be modularly constructable, which will allow us to fit the machine more easily into existing spaces, as well as use the standardized parts to reduce build costs while ensuring longevity,” commented Batchman. “This will result in lower initial costs and lower operational costs over the long term.” Exeter Engineering is hopeful that the modular capabilities will increase the demand for smaller machines in markets that operate seasonally, including Mexico.

Presence across North America

Interested in seeing the Sidewinder in action? There’s probably one close by. In the past seven years, 30+ Sidewinder machines have been installed in the US, Canada, and Mexico. In the US, they have been installed in California (running on citrus, melons, and bell peppers), Nevada (melons), Washington (onions, melons), Arizona (melons), Michigan (bell peppers, cucumbers, tomatoes), Florida (bell peppers, cucumbers), and North Carolina (tomatoes). In Canada, Sidewinders are used to sort and grade potatoes, bell peppers, cucumbers, and tomatoes. In Mexico, Sidewinder installations run on bell peppers, tomatoes, cucumbers, zucchini, and multiple other soft squash varieties.

For more information:

For more information:

Boomer Batchman

Exeter Engineering

Tel.: (+1) 559-592-3161

[email protected]

www.exeterengineering.com