Roussel Onions has been processing fresh onions for more than 25 years. This Belgian onion peeling company serves the Belgian, Dutch, and French markets. It is now also increasingly focused on the United Kingdom. "We find that an extremely interesting market," says Jan Vandenabeele. "We've been operating in the well-known markets for more than 25 years and always will. But everyone knows us here. The UK market's much bigger, which certainly holds plenty of prospects for us."

Trade shows

Roussel deliberately opted to focus on the UK. "They import about half of the onions they need, so there are opportunities aplenty for us," add father and daughter Pol and Charlotte Roussel. "Lots of Asian dishes are consumed there too, which widely use onions, garlic, and ginger. That's the holy trinity of Asian cuisine. That also ties in with our FAIA collaboration."

During the pandemic, contact was generally done online or telephonically. Now, people are finally allowed to meet face-to-face at trade shows again. "We introduced our FAIA brand (a Roussel, Waterman Onions, Biesheuvel, and Sawari Fresh collaboration) at Fruit Attraction in Madrid. After that, other companies and we could finally participate at Fruit Logistica," continues Jan.

"There, we managed to reconnect with potential business partners; something that's much easier done in person. We made several interesting contacts, especially in the UK. It goes far smoother this way, instead of the hassle with Teams and email. We now want to develop these new relationships further."

Niche market

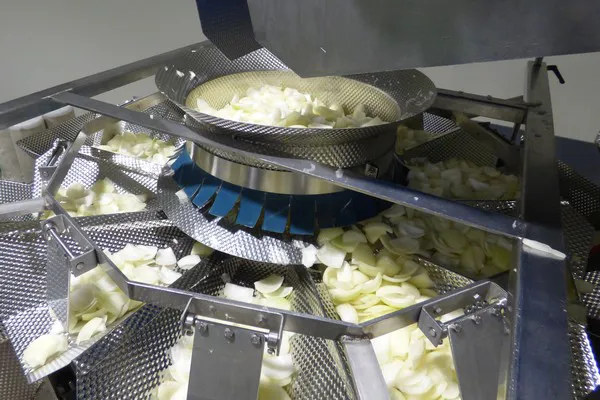

Pol says processing fresh onions is a true niche market. "Fresh onions make up maybe ten percent of the processed onion market. Customers very deliberately choose this product. Industrial tomato sauce processors, for example, are more likely to opt for freeze-dried onions or onion powder. But large pizzeria chains, for instance, usually use fresh onion rings on their pizza; something consumers expect. However, this requires certain expertise because you're working with a product with a more limited shelf life."

"That's where we distinguish ourselves," adds Jan. "We buy about 75% of the unpeeled onions within a 30km radius, except for our French clients' specially requested onions. We do all the peeling, processing, and transportation ourselves."

"That's where we distinguish ourselves," adds Jan. "We buy about 75% of the unpeeled onions within a 30km radius, except for our French clients' specially requested onions. We do all the peeling, processing, and transportation ourselves."

"Some UK processors use peeled onions from, say, Poland. That means there's a lot of transport and time between peeling and destination. That does the onions' quality and shelf life no good," he explains.

"The trick is to get the onions packed and delivered as quickly as possible. We can offer our English buyers the same service as our Belgian ones. We're near the Dover-Calais crossing, so we do the entire process, from a to z, in one day. The unpeeled onions arrive in the morning, are processed, and in the afternoon, we transport them. They are delivered, in any desired format, the next day. It can't really be any faster than that."

Innovations

Looking ahead, this family business is paying close attention to automation and packaging innovations. "We're always looking for even more automated processes," says Charlotte, "but these machines or technologies must, of course, be entirely up for the task and sufficiently reliable. It's hard to sort onions optically."

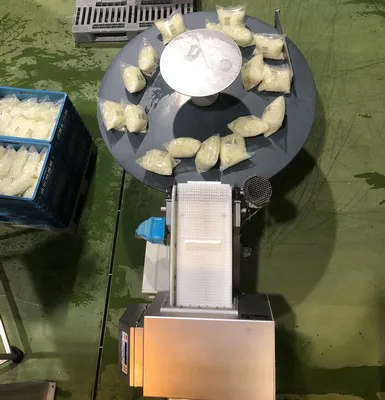

"Unpeeled onions can look perfect, but it's sometimes only after you peel them that you see their internal problem." The company also follows packaging developments closely. "We'll be installing a completely new packaging line, which is far more automated," Charlotte says. "Where possible, we automate, but if the technology isn't yet fully ready, we wait before taking the next step."

"Everyone's also trying to find more ways to package their goods sustainably, to which we're certainly open. For example, our clients and we are increasingly looking for alternatives, such as Big Boxes, to the traditional disposable wooden pallets. There's still some resistance to this because buyers have used those wooden pallets for 15 years. Change isn't always easy, but buyers are noticeably optimistic and want to participate in this sustainability effort. In time, we want to start minimizing things like 'single-use' packaging," Charlotte concludes.

For more information:

For more information:

Roussel Onions

221 Ieper Street

8560, Moorsele, Belgium

Tel: +32 (0) 565 05 306

Email: info@rousselonions.com

Website: www.rousselonions.com