Shipping patterns and schedules have become very erratic in the past year. “There are so many pieces to a logistics puzzle,” says Christian DeBlasio, CEO of Purfresh. “This past year has shown us how labor shortages at field and packing house level, as well as social distancing requirements have reduced farm level capacity. Additionally, increased shipping rates, and reduced capacity at ports have significantly impacted the time it takes for produce to make its way to the consumer.”

Unknown transit times

Just to give an idea of how erratic things are, DeBlasio provides an example of shipping mangos. They are shipped from Northern Mexico to New Zealand through the port of Los Angeles. Usually, the total journey is about 17 or 18 days. However, because of west coast port delays, transit time has become unpredictable, and the duration of the journey has become unknown. This volatility could severely impact quality of produce upon arrival, resulting in loss of product, additional food waste, and financial losses.

Farm to destination data availability

How can shelf-life be monitored during transit and how can cargo owners respond if a journey unexpectedly takes longer than anticipated? “Until recently, there was very little that could be done as no integrated solutions were offered to track data while the cargo is on the water,” DeBlasio shared. “Companies involved in international cargo shipping all offered piece solutions,” he added.

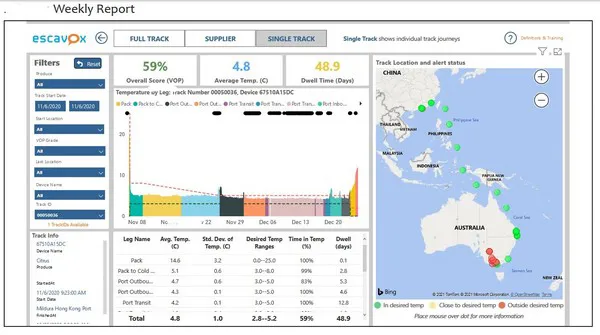

However, recently Purfresh started working on a solution with Escavox and the partnership allows the companies to offer a true end-to-end farm to destination service with uninterrupted data supply. “Our real-time monitoring and controlled atmosphere capabilities have been integrated with Escavox’s cloud that tracks data from point of origin to destination,” commented DeBlasio.

Cerlia Qu with Purfresh shows the Escavox tracker.

Cerlia Qu with Purfresh shows the Escavox tracker.

Real-time decision making

Established in 2018, the Escavox model involves embedding a small data tracker with the fresh produce from harvest origin to retail destination. All of the services and solutions of Escavox are live on land but not while on the ocean, when cargo is inside the ocean container, but Purfresh is able to fill that gap by having their data ported to Escavox.

As a result of the integration, customers have access to real-time data during any moment in time. They can see the location of the produce, how product has been managed through each transition point, and what the produce has experienced in terms of temperature, distance travelled, and dwell time. This information helps customers in making decisions as to where to sell their product, how fast to sell it, what price to sell it at, etc.

According to DeBlasio, there is almost no other existing farm to destination retail service that provides a complete data linkage that allows for so many decisions to be made for produce in real-time, along the way. “We are thrilled to partner with Purfresh,” said Luke Wood, CEO of Escavox. “Having their live, on-ocean data feed integrated with the Escavox end-to-end platform creates an industry best practice system for real-time, in-transit, perishable cargo decision making.”

Escavox CEO, Luke Wood.

Escavox CEO, Luke Wood.

Currently, the first shipments that combine the technologies of Purfresh and Escavox, delivering full journey cloud transparency are underway. Grapes out of Australia are on the water to China and South Korea.

Tracking of grape shipment. Click on photo to enlarge.

Tracking of grape shipment. Click on photo to enlarge.

San Francisco based Purfresh calls itself a global leader in controlled atmosphere solutions, ozone protection for fruit, and live data monitoring for any cargo transported overseas in temperature controlled ocean containers.

For more information:

For more information:

Christian DeBlasio

Purfresh

Tel: (+1) 813-546-0274

cdeblasio@purfresh.com

www.purfresh.com

www.intellipur.com