Paper packaging for fresh produce no longer surprises European consumers. Paper-packed potatoes have been widely used in France for almost a year and are the norm for shoppers there. This is also to be the case in other countries, although they are not yet legally obliged to such changes, although they are slowly introducing paper packaging as an ecological alternative to the ubiquitous plastics, says Marta Paprocka, marketing manager for Polish packaging manufacturer Silbo.

"Carrot producers are starting to use paper packaging as well. This vegetable is a bit more demanding in terms of packaging, as carrots are sensitive to moisture loss, which requires a proper barrier. In addition, carrots are almost always washed before the packaging process, which is why the water resistance of the packaging is so important in this case," Paprocka explains. "Also, the shape of the vegetable itself can be a problem because oblong carrots during packaging on vertical machines can damage the packaging material. In addition, there is the marketing aspect - sales depend on the display of the goods, so it is necessary to ensure proper presentation. Carrots should be visible, hence the need to pack vegetables in transparent materials or in packages with a window."

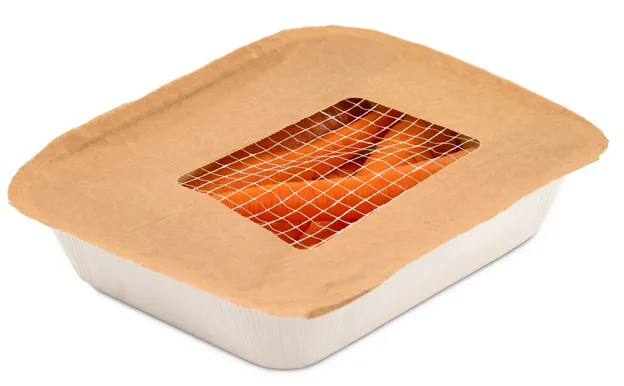

Silbo is introducing the first paper packaging for carrots to stores, Paprocka says. "When designing this packaging, we took into account all aspects, from the safety of packaging and storage, through marketing guidelines, to the ecological value of the packaging material. Paper packaging developed at Silbo has an increased moisture barrier, which gives the packaging adequate protection against water loss, and at the same time, makes the packaging durable. The product is properly ventilated thanks to the perforation in the packaging. We can cut small holes or larger holes in the packaging in virtually any shape, according to the customer's wishes."

This is important because, thanks to such technology, carrots are stored on store shelves in accordance with their shelf life, and paper packaging does not shorten this period at all, Paprocka explains. "Another novelty is the use of windows with transparent cellulose foil, which not only allows you to perfectly present the product but also does not interfere with the recycling process of the packaging material. We are very satisfied with the work on this packaging, it was a demanding process for the entire team, especially in terms of technology and selection of appropriate adhesives, because, as always at Silbo, we only work with biodegradable adhesives."

Paper packaging for carrots is a novelty. It has its obvious ecological advantages and can successfully replace plastic packaging, Paprocka emphasizes. "This is a more expensive alternative because, of course, you have to pay more for this kind of packaging than you would for a simple plastic bag. However, the arguments in favor of switching from plastic to paper packaging are getting stronger.

"First of all, consumers are more and more aware and sensitive to environmental protection, and as they declare in research, having an alternative, they are more willing to choose planet-friendly packaging. Secondly, it is also an opportunity for manufacturers to stay ahead of the competition. We can expect that European and national laws will become more and more restrictive and will oblige producers to reduce plastic waste. Those who do it early enough can gain a lot in the competitive and difficult market of fresh vegetables and fruits. Thirdly, there is an increase in sales of products packed in paper materials. This can be seen in the German market, where the interest in ecological packaging is quite clear."

"Packaging manufacturers also have to keep up with such trends. Silbo offers paper packaging for carrots in the form of conventional pillow bags with windows, in the form of cellulose or linen mesh, which are suitable for vertical packaging machines, as well as paper flow-packs suitable for horizontal packaging machines. In addition, we have developed paper top-seal lids for carrots packed on trays, as well as paper wrappers, which have already been used, for example, for packaging asparagus," Paprocka concludes.

For more information:

Marta Paprocka

Silbo

Email: [email protected]

www.silbo.pl

www.silbopackaging.com