In recent years, shelf-life extension technologies have grown vigorously as many companies saw an opportunity to tap into the hot topic of reducing food waste. “The produce industry is increasingly focused on food waste, and we saw an uptick in a genuine interest in post-harvest shelf-life extension solutions,” says Anthony Zografos, PhD, with Akorn Technology, founded in 2019. Changing lifestyles and an increased health awareness have resulted in consumers particularly being interested in solutions that don’t rely on chemical or petroleum-based ingredients. “We designed a truly 100 percent natural, effective, and affordable coatings platform, which had been elusive for other new entrants as they focused more on speaking to investor emotions than logic,” Zografos shared. “Then, they simply failed to deliver actual customer and investor results.”

Akorn’s shelf-life extension product is a coating that contains three active ingredients instead of one. These ingredients can be controlled independently to offer a solution for every crop and every use case. Specifically, Akorn Natural™ coatings include:

- A vegetable protein to control ripening speed.

- A plant wax to control moisture loss.

- A vegetable oil to control color development.

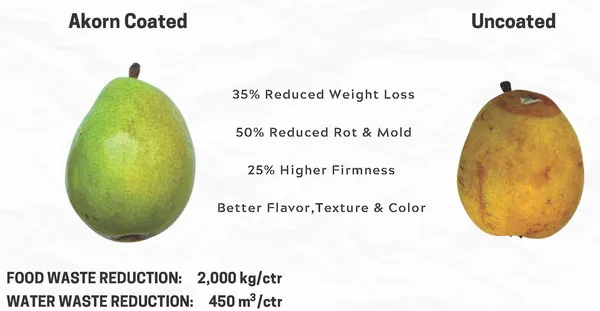

Akorn coated pear versus uncoated pear.

Major breakthrough

“Our fundamental breakthrough was in functionalizing a corn protein that has long been known as an excellent encapsulating film. This is important for two reasons,” Zografos commented. “First of all, our protein helps regulate respiration or breathing.” Traditional waxes have focused on transpiration or moisture loss.

“Frankly, our customer discovery process found that water loss is at best a secondary concern for growers and shippers. A pear with less water loss can still be mealy, rotten, overly ripe, or have an unattractive color. Reducing water loss on a product that contains any of these defects doesn’t trigger an increase in pear sales.” Secondly, the encapsulating film in Akorn Natural™ coatings allows for the addition of 100 percent natural waxes, oils, or other functional ingredients that are necessary for a specific fruit. “We deliver what is referred to in the literature as a composite multifunctional coating. In the past, this would have required multiple successive applications. We are able to do it in a single application. It is a major breakthrough in edible coatings.”

Affordable add-on

The application of Akorn’s coatings is similar to conventional wax and it’s effective on most fruit types that run through a packing line. “This ranges from tree fruits like apples and pears to stone fruit, and tropical fruit like mangos and avocados. We’ve also had success with pineapples and citrus. Additionally, early results on kiwi fruit are quite promising,” explained Xander Shapiro with Akorn. It’s preferred to apply the water-based coating with a simple spray bar and roller brush system.

“When adding to an existing line, it’s an easy and affordable bolt-on improvement.” The product can also be effective via a drenching application as long as the coated fruit can fully dry before packing. Customers often ask about applying the coating on soft fruits like strawberries and raspberries. “However, our water-based post-harvest coating is sprayed on the fruit and then needs to dry. Given that soft fruits are largely field packed and rarely run through a washing and drying system, shippers prefer not to add water due to the perishability and fragility of soft fruit,” Shapiro commented.

Akorn is plug-and-play on existing waxing systems.

Akorn is plug-and-play on existing waxing systems.

Global availability

Akorn’s coatings are available everywhere. Since they don’t contain any GMOs, or anything oddly engineered that requires a long regulatory process, the coatings can be sold around the globe. “All our ingredients are 100 percent natural, plant-based, and often upcycled. By drinking Akorn Natural™ coating, I’ve shown my customers that it’s safe as it is essentially made from food,” Shapiro added.

One mango packer in Africa reported that he had been able to reduce losses in the post-cold storage of mangos by nearly 50 percent. “Holding the mangos in cold storage helps smooth out the season and deal with the occasional hiccups in global supply chains,” Shapiro explained. “The math is not complex when half of the mangos that were formerly tossed in a field are now sellable.”

This impacts local communities favorably as it doubles the income and enables customers to operate more efficiently and profitably. In addition, it helps their importers and retail customers best serve consumers. “We’ve been consistently hearing that our customers are pleased with the results from using Akorn.”

For more information:

Xander Shapiro

Akorn Technology

Tel: +1 415-793-4995

[email protected]

www.akorn.tech