In 2007 when Sara Osborne bought Peters Cranberries, her father-in-law’s cranberry farm on the misty Oregon Coast, she didn’t expect cranberry prices to soon plunge by 80 percent, sending the whole industry into shock. Yet that is exactly what happened, so Sara was very relieved to eventually land a big contract with one of the world’s largest fruit packing companies.

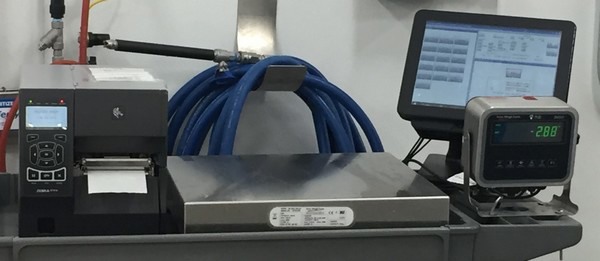

However, that company required barcoded labels on every box. Sara shopped for a labeling system and chose Simba, from Dynamic Systems, Inc., which combines robust barcode software with a full suite of leading printers, scanners, and touchscreen computer tablets.

“At the time, I didn’t care about the bells and whistles,” she says. “I just wanted labels.”

However, within a few years as the industry changed again, Sara found order sizes varying more even as customer numbers grew. What had been a simple business of supplying a couple of big customers with standard shipments had become much more complicated.

Soon, Peters Cranberries added more fruit from other growers, turning its processing center into a transshipment warehouse. The company also had to handle demand for specialty berry varieties, such as those suited for sauces. “As challenges grew, Simba proved its real value,” Sara said.

“I became addicted,” she continued. “I realized that this labeling system of ours could also help me stay ahead of rapidly moving inventory, because once something is barcoded there’s no more data entry, and the system makes it easy to track, organize, and re-box as needed, keeping great records on several orders at once.”

“One grower-partner was amazed at my paperwork because she was still managing orders as we once did, with a bunch of spreadsheets and notes for each. She’s now planning to buy this herself.”

Simba also proved itself in industry quality-control audits, such as those from the Cranberry Marketing Committee and the USDA Good Agricultural Practices program. When auditors ask where a box of berries was grown, stored or shipped, Sara no longer searches through drawers, binders and, hard-drives for records; running a report takes just a couple of clicks.

Sara also finds it helpful to have a system user-friendly enough for her extremely seasonal business.

“Because we use our system primarily during fall harvest, I have to be able to come back to this software after nine months away without too much relearning. That means having both intuitive software and great tech support.”

Now, fourteen years on, Peters Cranberries is going strong, meeting the challenges of a growing network of customers and growers, and more variety in products and orders.

Sara has no doubt that more changes are ahead, but, she says, “When changes come, we’ll be ready.” For more information:

For more information:

Rob Freeman,

Dynamic Systems, Inc.

Tel: 800-342-3999, ext. 208

Direct: 425.284.1662

robf@dynamic-systemsinc.com

www.Dynamic-SystemsInc.com