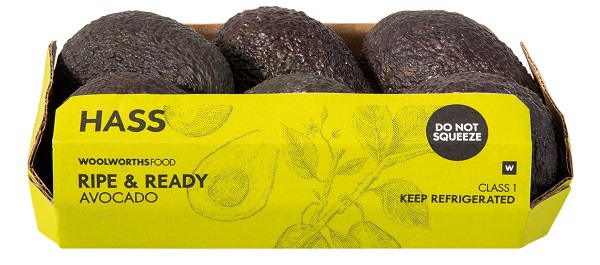

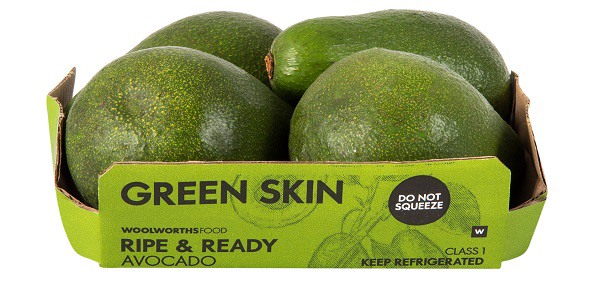

Shoppers at Woolworths will be seeing a lot more cardboard packaging in future, like the kraft board cartons for their 'ripe and ready' avocado, rolled out to all varieties this year, and speciality tomato ranges.

“The transportation of ‘Ripe and Ready’ avocados from farm to distribution centre to store and then into customer’s homes requires a gentle but robust packaging choice,“ the company notes. The 'ripe and ready' avocado kraft boxes (made from 63% recycled paper) equates to an annual plastic saving of between 35 to 40 tons and is covered with a fully recyclable shrink wrap.

Photos supplied by Woolworths

Photos supplied by Woolworths

The new packaging is the result of several years of development, trialling many different types of cardboard before eventually settling on locally-sourced kraft board which, unlike other paper pulp-based holders, were found to hold their shape when shrink-wrapped while offering better protection against bruising. The ripeness level of greenskin varieties, particularly Fuerte, has to be spot-on, otherwise compression bruising becomes an issue, notes Frans Gelderblom, Senior Technologist for fruit at Woolworths. “On Hass and Gem we haven’t had any issues.“

The only additional step that has been added in the avocado packhouse, Gelderblom notes, is placing the cardboard punnets in coolers the night before use, to soften them up a bit.

Moreover the boxes are covered with a fully recyclable shrink wrap, the same that would wrap around cartons of soft citrus, made of South African-manufactured Superthene and polyolefin polymer, which is fully recyclable, unlike the PVC of before.

“We have been working closely with our suppliers and packaging manufacturers for over two years on this new design, including extensive customer trials over the last eight months with the various avocado varieties. We are confident that the new packaging will deliver the functionality that we need. Kraft board is an excellent packaging alternative to plastic in that it is 100% fully recyclable, biodegradable and Forest Stewardship Council certified,” says Latiefa Behardien, Head of Foods Technology, Safety and Good Business Journey at Woolworths.

“We have been working closely with our suppliers and packaging manufacturers for over two years on this new design, including extensive customer trials over the last eight months with the various avocado varieties. We are confident that the new packaging will deliver the functionality that we need. Kraft board is an excellent packaging alternative to plastic in that it is 100% fully recyclable, biodegradable and Forest Stewardship Council certified,” says Latiefa Behardien, Head of Foods Technology, Safety and Good Business Journey at Woolworths.

Woolworths has made inroads into their plastic use elsewhere in the fresh produce aisles, for instance reducing the weight of grape punnets.

They have fine-tooth-combed all of their products for ways to save in plastic and other materials: because the packaging of their range of prepared meals has now shifted to recyclable paper board, where possible, the company has avoided the use of 4.3 million plastic punnets. Printing directly onto the paper board saves them 6.1 million labels.

For more information:

For more information:

Diane Peterson

Woolworths

Email: custserve@woolworths.co.za

https://www.woolworths.co.za/