The degreening process consists of changing the external coloration of citrus fruits by controlling the different factors that affect the fruit, such as temperature, ambient humidity, and the concentrations of oxygen, carbon dioxide, and ethylene, the latter of which acts as a catalyst for the fruit's metabolic changes.

The degreening process doesn't affect the fruit's physiological maturity (sugar, acidity, and juice percentage). The maturity index must conform to the parameters established for each variety by law.

The degreening process is carried out in chambers equipped for this purpose, where producers can control the aforementioned factors.

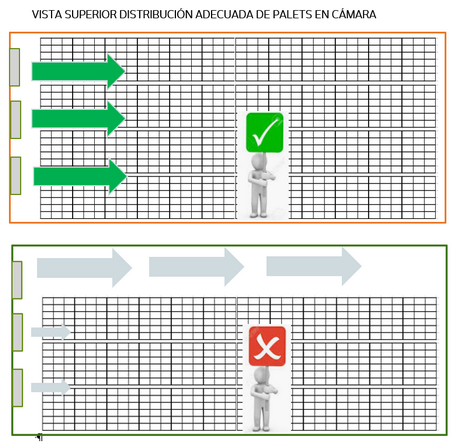

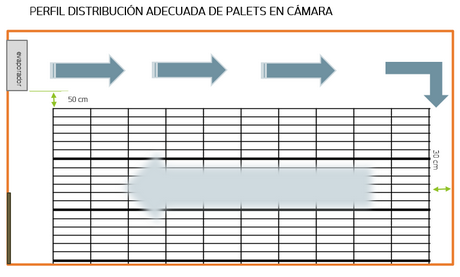

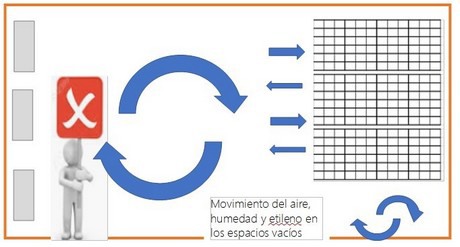

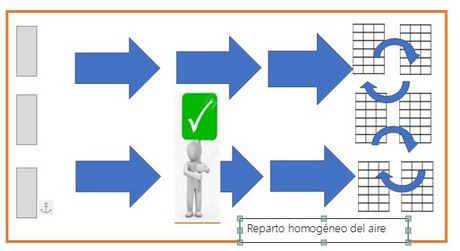

The way the fruit is stacked and how the air moves inside the chamber is very important to shorten the time that the degreening process takes and to achieve a uniform coloration throughout the fruit regardless of its position within the chamber.

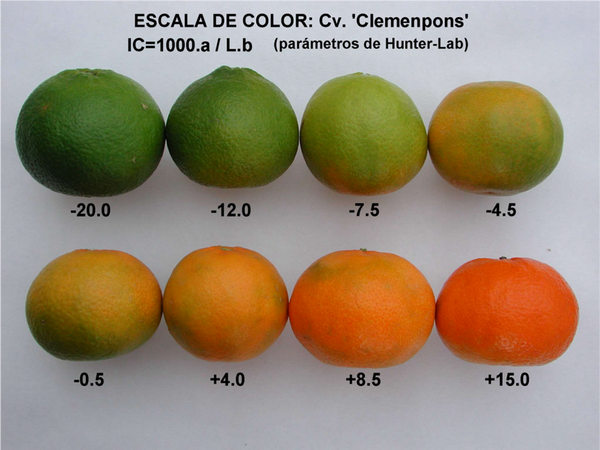

In addition, it is essential that the fruit that undergoes the process has adequate coloring so that it acquires a final color similar to the degreening variety. Air must move at a speed of 14 to 20 meters per minute, which can be easily measured with a portable anemometer. The reading should be done at various points in the chamber with the fruit stacked, i.e. in its corridors, the space between the rows of pallets, and the free area at the entry zone.

The chamber should be completely clean and disinfected before the degreening process is carried out to maintain the health of the chamber and the fruit. Using aerosol disinfectants (DYBAC) before entering the fruit into the chambers is also recommended. Later, during the degreening process, aerosols with no residues, such as SANI AEROFRUIT, should be periodically used to maintain environmental health.

The fruit treated by drencher must be left to dry for 12-24 hours so that it is free of water on its surface when placed inside the chamber so that it achieves having a uniform color over its entire surface and to avoid physiopathies. Free water slows down the gas exchange process, delaying the start of the degreening process. In addition, prolonged contact with liquids can cause pathophysiology in the most sensitive varieties.

The pallets should be distributed in the chambers to avoid having a closed accumulation at one end. This allows the air and its components to be distributed more homogeneously over the fruit. The degreening process can be done manually or automatically.

|

|

You can find out more about citrus degreening conditions in the following Technical Memo from Sanifruit.

You can find out more about citrus degreening conditions in the following Technical Memo from Sanifruit.