Martin Bourgondiën, as Commtrad machines’ owner, sells Select machinery to fruit and vegetable companies.

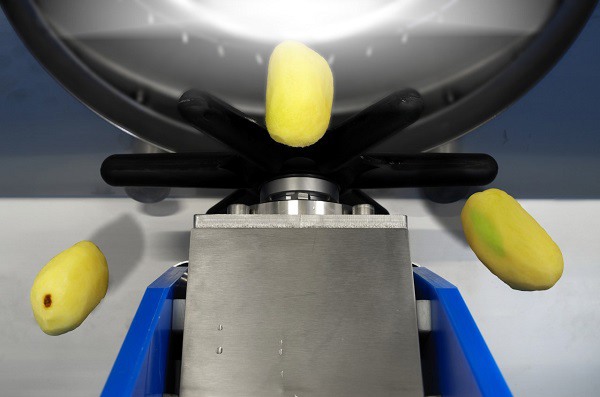

close-up of the 6-legged finger rotor on the Arcus

The client Martin just visited has a new Select Arcus optical sorter. It replaced the 16-year-old Agroselector that was standing in the company’s peeling and fries department. “This is that latest-generation optical sorter. It sorts washed and unwashed, peeled ware potatoes. This machine is great for other vegetables like Brussel sprouts, carrots, and leeks, too,” explains Martin.

Arcus

The Arcus was introduced to the German market two years ago. It compliments Select’s range. That already consisted of the Cinderella, a sorter for smaller products like baby potatoes and fries. But, it has the same technology that the Arcus now uses. “The Arcus’ compactness stands out,” explains Martin. “You wouldn’t say such a simple-looking machine could sort optimally, but it can. Thanks to its small size, this sorter can easily be installed on the processing line. The Arcus is built entirely from stainless steel too. So, it easy to clean and maintain.”

production line containing two Arcus potato sorters at a potato processing company

0.05 mm2

Enough about the machine’s exterior characteristics. The heart of the sorter has four cameras, used for 3D inspection. “These cameras work fast. They can carefully inspect a product, down to an area of 0.05 mm2. For the sustainability aspect, the machine's also equipped with LED lighting. That means you don’t need to replace the bulbs, which, in turn, means lower maintenance costs.”

This new optical sorter also has a higher capacity. “This machine can process up to 20 tons/hour. At least the Twin version can, which makes it highly suitable for potato packers," says Bourgondiën. "For peeled potatoes, we’re looking more at 7.5 to 8 tons/hour. Yet, at a higher capacity, the machine retains its ‘soft’ treatment of products. It has a large touchscreen and various sorting options too. These are convenient and give insight into the products’ sorting. You can, for example, control all the machine’s cameras.”

the arcus optical sorter

Sorting

To sort the potatoes, clients can opt for multiple sortings. “We had a client who wanted his potatoes sorted into nine categories. We simply adjusted the machine. Sorting can be done using air pressure and a six-fingered rotor. These sort the potatoes quickly - up to 12 to 14 per second. I prefer the rubber spinning wheel. It’s more maintenance-friendly than working with air valves. The finger rotor not only rejects or passes the potatoes; it does so by size or quality too.”

More information:

Commtrad

Martin Bourgondien

Bourgondien.commtrad@hotmail.com

Tel: 0032 3 213 2293