2020 has been a tough year for businesses around the globe. The COVID-19 pandemic has taken its toll on all sectors and brought to light many shortcomings in daily procedures. While fruit and vegetable processors were considered essential and were mostly able to continue their work, higher costs and labor shortage were issues they had to face. “Despite the pandemic, we expect investments in the fruit and vegetable sector, as these problems have to be addressed as quickly as possible”, says Nick Maglio, director of marketing at ProEx Food, LLC.

“Here at ProEx Food, our culture and delivery outcomes are orientated around enabling you and your produce processing / packing business. We help you strategize how to increase your capacity and throughput, help you pivot to and/or add new product categories to your operation, help you solve for your operational problems, and help you solve for labor availability. We go out of our way to deliver value-orientated results that you will realize quickly. We are your one-stop-shop for growth strategies.”

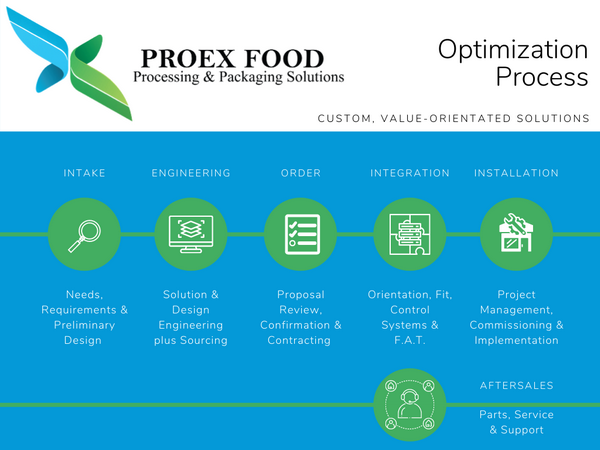

There are different steps that ProEx Food follows to find the perfect complete solution for their customers: “Timing is often crucial in this process. We want to help you identify the right solution and have your proposal ready to go for your internal approval processes when you need it.” They recommend to get ahead of this, and be ready to submit prior to the deadline. “This gives us time to roll up our sleeves and work on a solution for you. It also gives us time to partner on and refine the details before you make your push.”

Sweet corn processing is one of the specialties of ProEx Food.

Nick stresses the importance of aligning ROI-guidelines and issues in the process that a company wants to address: “We want to find a good middle ground between incorporating new goals, such as new product categories, capacity expansion or other needs our clients may have. At the same time, we need to make sure to stay within a payoff timeline and reduce direct and indirect cost.” ProEx Food achieves this by reducing labor through automation and delivering quality machines that require less maintenance, Nick says.

“Most importantly, the majority of equipment and solutions in our catalog has an ROI within 24 months. We work to understand the real needs to first lay out an ideal solution and narrow it down to the perfect fit.”

Another extremely important factor nowadays is sustainability, both in terms of longevity of the equipment as well as considering food or packaging waste. “This could be everything from getting the most useable product to reducing waste due to bruising/damage to end waste. We have potato processing customers that have a slurry at the end they need to truck away. We work with them to find a way to remove and separate the water that can go safely into the sewer/drainage from the solids that have to be trucked out, mitigating the CO2-footprint and potential to spill.” They also address the need to reduce water consumption or to work on reconditioning and recirculation. “Our peelers are designed to use less water overall. How about the boiler system – old and inefficient?”

Waste from potato processing

Nick is convinced: “We’re different than traditional manufacturers, integrators and engineering companies you may have dealt with in the past. We put in the effort to understand your business, and ask probing questions to get to know you, your team, and the items that impact your day-to-day and long-term objectives. We apply our investigation and the internal steps in our process so that we can design and recommend the optimal solution for you. This can include our engineering capability, our equipment, technology and solutions from our global partner network, or ways to help you line up financing and investment methods for your equipment.”

For more information:

Nick Maglio

Director of Marketing

ProEx Food, LLC

marketing@proexfood.com

www.proexfood.com