Fresh produce is not an easy business. You are always reliant on the weather conditions and how well the crop performs that year. Then, if you transport it to other destinations, you need to make sure this happens under the right circumstances so no crops are wasted. How to make sure nothing happens during the transport?

“One critical source for a good management of your product during transport is a reliable data logger. However, there are many choices on the market and not all of them are the right one. We did a little research to see how well all data loggers performed that are now available. We found numerous inadequate products, especially when we talk about reliability.” Said Austin Gu from Cydiance.

Real traceability

“First of all, we found a difference in the way temperature was collected. All loggers collect temperature, with 2 options: an “internal NTC” or a “digital sensor”. NTC is a much cheaper option with lower support requirements from the system. Meanwhile NTC requires manual calibration which takes at least 2 hours for a small batch, and it’s almost impossible for such process during mass production. While a digital sensor is more expensive and requires more internal resources to support it, it is already pre-calibrated. To make sure it works perfectly we need to guarantee a more stable system support, especially at low temperature and low voltage conditions so it will still collect temperatures.”

Insufficient low temperature performance

“Furthermore, data loggers should work under very cold circumstances, since most transport for fresh produce needs cold storage. When something happens with the refrigerator and the temperature drops too much, the records of the logger are most important to see what happened.”

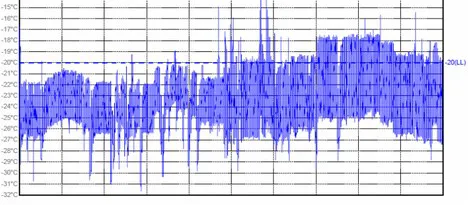

A Cydiance C1 used intensively in frozen condition.

“We did an experiment and tested different data loggers for the temperature of -18 degrees. All data loggers were indicated to record temperatures on a range between -20 and -30 degrees. However, when we tested them 80% failed. We are not going to name any to avoid misunderstandings but you would have to pay attention to this.”

Failure proof strategy

“All electronic devices will make mistakes, therefore a “failure proof strategy” has to be deployed internally. For example, an anti-static proof, compatibility, low voltage, non-stable connection etc. USB temperature logger should be prepared for all these unexpected coincidences, and make sure integrity of content is kept.”

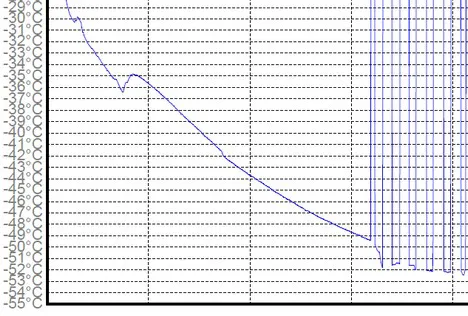

A Cydiance C1 initiated protected strategy after more than 24 hours in extremely low-temperature condition.

“We have a very complex system on this simple product, both hardware and firmware, to ensure it fixes itself when something happens. And just recently we noticed the importance of this, as we are having a lot of new clients now coming to us with this kind of bad experience with other companies. Recording temperature is easy, providing complete and reliable data is never easy.” Concluded Austin Gu.

For more information:

Contact: Austin Gu

Cydiance Technology

Email: info@cydiance.com

https://cydiance.com/