Following the drop in blueberry prices, some companies have been slowing down their investments. Still, the best bet is to offer a premium quality fruit: a firm blueberry, of maximum hardness and with the bloom intact.

"These characteristics can only be obtained in two ways: with manual handling and packaging (high labor costs), or automation with multi-headed linear machines," explains Enrique Azcárate, manager of Envapack, an engineering company specialized in the design and manufacture of blueberry packing equipment.

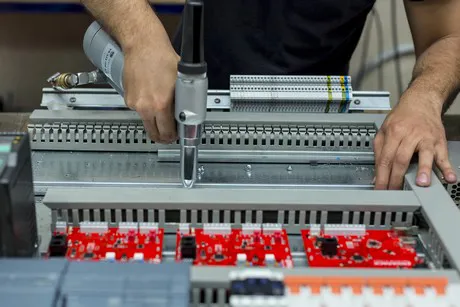

E4000 multi-format linear weighing machine

"The best quality is achieved with manual handling and packaging, and only a linear system can replace that," explains Enique Azcárate.

The manager of the company says that "producers are more focused on delivering quality, so they need to prevent their blueberries from getting hit or bruised inside the multi-headed weigher."

"Using this technology, the fruit is packed with speed and precision, and most importantly, preventing unnecessary hits or friction, which could spoil the fruit. Also, the versatility of the packers allows them to adapt to any kind of container."

Turnkey project

Turnkey project

"Time saving, ease of maintenance and simple cleaning are factors that allow you to work more efficiently, as well as to save in daily maintenance costs, compared to other multi-headed machines," says Enrique Azcárate.

Envapack has quadrupled its sales in 3 years and has gone from having 150 square meters of facilities to 1,500. Its machinery, created 100% in Spain, including the software, is starting to be exported to Italy, Peru, Chile, etc.

According to Enrique Azcárate, betting on the quality of a 100% Spanish product comes with some guarantees. "The closeness to the customer and the product's origin allow us to offer a personalized customer service and the quick solving of any technical problems."

"Now that the blueberry craze is slowing down, some companies tend to stop investing, but in fact, the only way to make a profit in this sector is to invest in innovation and automated packaging."

"Also, the time saving and versatility of the machinery allow you to maximize the profits," says Enrique Azcárate. "For this reason, many producers with other more aggressive multi-headed machines have been showing interest in our linear multi-headed one," concludes Enrique Azcárate.

More information:

Envapack

Alcalá X cuatro, Nave 6

Alcalá de Guadaira, Seville. Spain

T: +34954911475

info@envapackenvasadoras.com

envapackenvasadoras.com