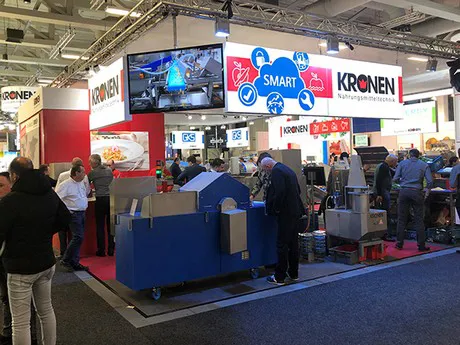

Food processing technology manufacturer Kronen premiered its new “SMART Machines” at Fruit Logistica 2019 in Berlin from 6 to 8 February 2019. They were shown live and in function and Kronen visitors experienced how “Industry 4.0” applications can work in Fresh-cut production. Further world premieres were on show as well: The thermal washing process DECONWA, which is the result of a research project, and the newly developed apple peeling and slicing machine AS 6.

Numerous visitors from more than 50 countries visited the Kronen stand at Fruit Logistica for experiencing the innovations and proven solutions, which were demonstrated live and in function by the family business Kronen. The international Kronen team, represented with about 20 countries at the trade show, was pleased by the big interest of the visitors: “By displaying the “SMART Machines” and the DECONWA washing machine Kronen presented two real pioneering achievements, which are completely new at the Fresh-cut market. We are very happy about the huge interest these innovations have met” says CEO Stephan Zillgith. “Especially the topic of Industry 4.0 is a very new one for many of the vegetable and fruit processors. Our goal was to show what can be possible in future. We are very pleased with the results of this year’s fair”.

Industry 4.0 in Fresh-cut: Kronen "SMART Machines“

“Industry 4.0” is actually reality in many areas already. It is all about the networking of machines in production. With "SMART Machines“ Kronen presents machines which are able to communicate over the internet, for example belt cutting machine GS 10-2 SMART, washing machine DECONWA SMART, vegetable spiral cutting machine SPIRELLO 150 SMART and pineapple and melon peeling machine AMS 220 SMART.

At Fruit Logistica 2019 Kronen displayed how SMART applications can work in Fresh-cut production. SMART Machines or an entire SMART Factory can transmit machines’ statuses into the Kronen Cloud in real-time. The production manager, technician or the foreman can monitor the production status of the machine or line on their laptop or mobile device from any location and at any time. The collected data helps to make production processes more efficient, for example in regards to productivity, quality and process reliability. By implementing predictive maintenance the user can prevent possible breakdowns.

The Kronen SMART solutions are modular: There is a basic module. Beyond, the SMART machines are individually adapted to the specific needs of the customers and the performance range can be expanded continuously throughout the future.

Innovations and a comprehensive portfolio in Fresh-cut

Besides, the following further novelties attracted many visitors:

Thermal washing process DECONWA: The new washing system disinfects apples for Fresh-cut fruit salads and increases shelf-life as well as consumers’ safety. By using temperature guided and controlled processes with a temperature around 50 °C bacterial load is reduced. Benefits:

- Without using any additives or chemicals

- Can be integrated into an existing processing line flexibly and can be transferred to similar products.

Optimized for application in cold rooms

The system was developed by Kronen in the context of a research project together with ATB Leibniz Institute for Agricultural Engineering and Bioeconomy and Mirontell Fein und Frisch AG. The project was funded by the Federal Ministry for Economic Affairs and Energy by a decision of the German Bundestag.

Apple peeling and cutting machine AS 6:

The multifunctional AS 6 is perfectly suitable for peeling, coring, wedging or slicing apples. It allows the processing of up to 900 apples per hour and thus, it is optimized for industrial application. There is the option to set up several machines parallelly to further increase capacities. The automatic loading, processing and outfeed improves the speed and efficiency of the process and guarantees ergonomic operation.

Next to these premieres, Kronen presented a range of developments such as vegetable and salad spin-dryer KS-100 PLUS, disinfection UVC Lock and dewatering system BDS 3000/800 as well as proven machines, e.g. belt cutting machine GS 20. And once again the visitors at the stand were delighted by the popular “Live Cooking”. The chefs Wolfgang Blum and Andreas Eigner offered inspirational and delicious Fresh-cut delicacies.

For more information:

Esther Müller

Kronen

Phone. + 49 (0)7854 9646-161

Email: esther.mueller@kronen.eu

www.kronen.eu