Buijsrogge Fruit is mainly specialized in the storage of pears for third parties (5.5 million kilos), in addition to its own production business and farm shop. "We are focussed on the long term storage of Conference pears," says Frans Buijsrogge. It always is a race against the clock to clean the plastic fruit crates in time before the new harvest. Together with Burg Machinefabriek, he developed a new machine that uses a brush to clean out coarse and stubborn dirt from the crates, before putting them in the crate washer. With success: "Clean is now really clean!"

"Because we are specialized in the long-term storage of Conference pears, these crates are released as last. There was always a lot of pressure to get them clean in time before the harvest. We used to do this by hand on the courtyard with a pressure washer, but we have more than 6,000 plastic fruit crates. This was a disaster, logistically speaking, and we were not satisfied with the results. For the customers it is important that the crates are free from juice, ground particles, and mould, so the new harvest can be stored," explains Frans.

Frans Buijsrogge and Michael Ots

Mechanical force needed

Frans presented the problem to Burg Machinefabriek. First, the existing crate washer was used, but it was not powerful enough to remove the stubborn dirt. Frans as well as Burg decided quickly that there had to be investment in a solid solution, which was realized in a brushing unit to clean the inside as well as the outside of the crates. "It was clear to us that mechanical force was needed to brush the dirt out of the crates. The way Burg Machinefabriek joined in the thought process was absolutely fantastic."

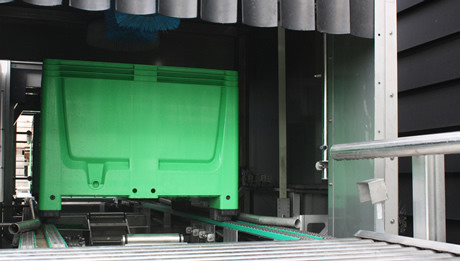

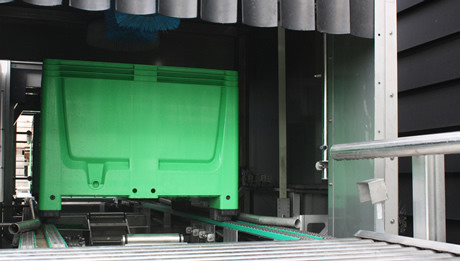

The machine, suitable for plastic as well as wooden fruit crates, works as follows: First, a crate is supplied to the Burg Brushing Unit (BBU), this happens over a roller or chain conveyor. The crate is taken from the conveyor by the machine. While the crate is entered in the machine, it is sprayed with cleaning solution by a sprinkler tube. As soon as the crate reaches the middle of the machine, it is clamped and centred by a clamping system. The crate is then brought up between the brushes by a lifting system. After the crate has reached its final position, the brushes are pressed against the crate and they start rotating. The brushes then follow the contour of the crate and go around the chest. After one round, they go in opposite direction. After the brushing has finished, the crate is brought down, unclamped, and transported out of the machine by the conveyor. After all the coarse dirt has been removed from the crate, the crate is automatically supplied to the crate washer, which cleans the crate thoroughly.

Less downtime

Less downtimeFrans has had his second season with the combined brushing unit and crate washer with total satisfaction: "The machine is perfect for me, just the way it is. I have one extra employee for the conveyer belt with a forklift truck. The machine has a capacity of 50 crates per hour and it is just fine for me. It has been considerable investment, because we invested in good material and we do not want to take any risks. Fruit producers who want to store their pears have to be sure that their fruit is in clean crates and stored in a clean storeroom. This cannot be doubted, it is our responsibility and it will result in less downtime."

Burg Machinefabriek is happy with the result. "We are happy to help customers with their own innovation, which is what we want to do with our business. Our engineers have been busy to design the ideal machine for a few weeks, but the result is something we can be proud of. We have not had the time to go to other producers to promote the system, but we see many possibilities to expand this machine in the market," says Michael Ots of Burg Machinefabriek in Kruiningen.

This drive for innovation is in Frans' genes. "I have always liked thinking about developments. We were pioneers at moistening the pears and we were one of the first producers that worked with plastic crates. At Burg, I can see the same wish to innovate the fruit production and processing. The efficiency of this machine is not immediately calculated, but we expect that it will literally bear fruit. There can be no doubt about the hygiene at our side. We cool and trade mostly the fruit of others. We now have that part under control. So now, we just have to hope that the fruit will make us money, because the last few years that did not really happen. At least we are ready for the coming season!"

For more information:

Michael Ots

Burg Machinefabriek Weihoek 11

4416 PX Kruiningen (Netherlands)

Tel: +31 (0) 113 - 50 13 73

Fax: + 31 (0) 113 - 50 21 08

E :

mots@burg-machinefabriek.nlW :

www.burg-machinefabriek.nlFrans Buijsrogge

Buijsrogge Fruit's-Gravenpolderseweg 118

4462 RA Goes (Netherlands)

Tel: 06 55 801980

fransbuijsrogge@zeelandnet.nl