Extending a product’s shelf-life has been an important goal for people at almost all points on the supply chain. Longer shelf-life means less product loss, less food waste, and more efficiency. Extending a product’s shelf-life can be done in different ways: some growers and breeders focus on developing more resistant varieties that specifically have longer shelf-lives, but other companies work on finding innovations that will help extend the shelf-life post-harvest.

Reducing food waste by extending shelf-life

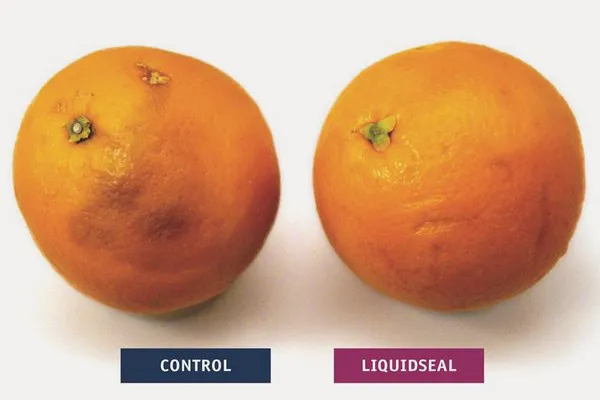

Victor Monster of Liquidseal Fruits says: “With a rapidly growing world population, there is an increasing demand to actually consume what we produce – in other words, to reduce food waste. We have developed a product that helps extend the shelf-life of citrus fruits and prevent product loss up to 30-40%.” The product is called Liquidseal and is a biodegradable and compostable packaging that consists of an ultrathin layer that influences evaporation and prevents the fruit from aging.

Victor explains: “Liquidseal helps protect each fruit individually against mold and weight loss. We aim to prevent product losses and increase both the transportability of the citrus and the product’s quality and performance throughout the supply chain, from field to fork. Currently our postharvest products are available for fruits with a hard shell like avocado, mango, and papaya, and we are working on adding more fruits to the assortment, specifically melon and pineapple. The current version of Liquidseal washes off easily with a quick rinse, but we are actually also developing an edible version of the packaging, which should make the product more accessible for a large variety of fruits.”

Mission of sustainability

Liquidseal should be applied directly post-harvest for best results. Victor says: “The product can be applied by growers, wholesalers, packers, or even importers. The preferable time to apply the product is directly after harvest, and the application process is actually quite easy – done through either dipping the fruit into the Liquidseal, or spraying it onto the fruit – and the application process can be efficiently integrated into the existing production lines.”

The product doesn’t only increase shelf-life, thus reducing waste, it also reduces the need for chemicals and plastic packaging. “Our mission is to extend the life of perishable agricultural products in a sustainable and cost-effective manner. Our goal is to make it easier for everyone in the supply chain – from grower to consumer – to reduce product loss and food wastage, and reduce the amount of chemicals used on our good. We aim to make a contribution to reducing food waste in the supply chain, thereby giving a positive impulse to the food shortage,” concludes Victor.

For more information:

Victor Monster

Liquidseal Fruits BV

Tel: +31 (0) 71 3014314

Email: [email protected]

www.liquidseal.nl