Since 2012, InspiraFarms Cooling have specialized in providing African agribusiness in the fruit and vegetable industry with the tools, technology, and expertise to significantly reduce food losses and energy costs and access higher-value markets. In 2022, InspiraFarms Cooling expanded these solutions, beyond cold rooms, packhouses and precoolers for the fruit and vegetable industry, to solutions for flowers and also into long-term storage solutions for potatoes and onions.

"Across all our solutions we have done installations across Kenya, Zimbabwe, Uganda, Tanzania, Zambia, Mozambique, Ethiopia, Rwanda, Benin and more," said Dave Zoetemelk, Director of Sales at InspiraFarms Cooling.

"Our decision to expand our solutions was primarily driven by market demand and the need for such solutions. As the market expanded, we recognized the need for reliable and efficient cooling solutions specifically tailored to the unique requirements of potato producers, distributors, retailers, and traders. In turn, these solutions ensure optimum temperature levels and appropriate storage conditions, which ensures minimized mass loss and the reduction in product quality."

In InspiraFarm's Cooling's focus markets (African countries) it is often hot, making the pace of deterioration noticeably faster, hence the critical importance of cooling. In Kenya alone, per season, 19% of produce is damaged or lost.

"Extrapolating these losses to the national production level, we can assume that 815,000 tonnes are damaged or lost each year, representing a value of around KES 12.9 billion (EUR 109 million). Additionally, the crop is still predominantly rain-fed across the country, therefore, some processors do not have a potato store, so they experience supply shortages in March/April and November/December. This is why long-term storage is important.

"Running an inefficient potato cold storage facility may be difficult and expensive due to the risk of product loss: improper temperature and humidity control can cause potatoes to spoil, shrink or develop sprouts, reducing their quality and shelf-life. Product loss can be cut down by proper storage protocols and monitoring crop conditions regularly. The most common diseases causing problems in storage are bacterial soft rot (blackleg, Dickeya) late blight, pink rot and leak, which are caused by improper storage such as high humidity."

Long-term storage solutions are the optimal solution for root vegetables such as potatoes, onions, carrots, garlic, and ginger or for fruits that can be stored for many months such as apples, pears, kiwi, cherries, oranges etc.

"This is obtained by adjusting temperature, humidity, airflow, and the balance of some key gases (CO2, nitrogen, oxygen) in the internal room atmosphere. Additionally, adjusting ethylene, which plays a significant role in the ageing process of many fruits and vegetables, including potatoes, is critical. Therefore, by adopting long-term storage solutions to slow down the ripening and ageing process, you maintain their quality, delay sprouting and extend their storage life."

For agribusiness and traders of these products, storing them for extended periods offers a competitive advantage. It enables them to meet the demands of distant markets, accommodate fluctuating supply and demand cycles, and optimise logistical operations. Additionally, for processing companies of value-added products such as potato crisps and French fries, long-term storage solutions allow room for uniformity in their supply, stable quantity and good quality for up to eight months. On a smaller scale, efficient long-term storage solutions can help farmers time the market or save their seed from season to season. On a larger scale, it enables communities of smallholder farmers to pool their harvests to time the market or sell to processors.

"For many products this is an essential strategy to replace imports and buffer price volatility risk, capturing more value out of the harvest or being able to feed food processing factories, such as chip production plants."

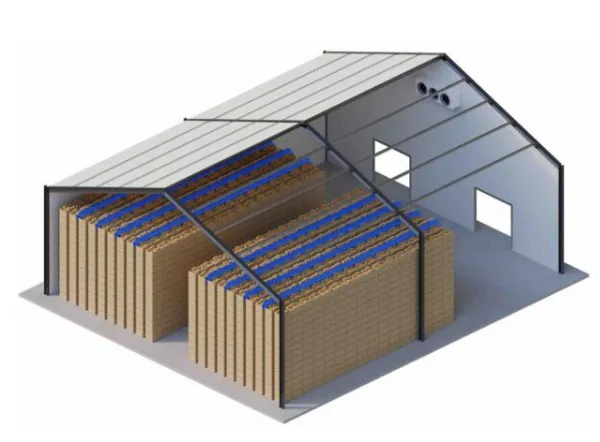

InspiraFarms Cooling long-term storage solutions offer modular and prefabricated storage structures, with special insulation, ventilation, and cooling systems for ensuring optimum temperature level and appropriate storage conditions, which ensures minimized mass loss and the reduction in product quality, with capacity ranges from 500 to 5,000+ tons.

The company offers insulated cold storage structures with doors, hatches, loading docks etc., while the tailor-made cooling solution drops produce temperature and maintains it. Also ventilation systems according to the product storage type, as well as air circulation with high-flow axial fans.

In addition InspiraFarms Cooling provides automatic air refreshment systems for tropical environments, replacing the more traditional hatches and humidification systems for maintaining optimum humidity during long-term storage. Wooden boxes for efficient storage of produce allowing the right ventilation are also provided.

"Our long-term storage can be powered by three-phase electric power. Single-phase is possible for small dimensions of up to 7 kW of cooling capacity. The power can be sourced through solar but as a hybrid, having the grid or a generator as backup."

"Our designs use energy-efficient designs and materials with walls and ceilings made of high-density closed cells PUR sandwich panels to ensure superior durability and energy efficiency in any climatic conditions. The full structure is lightweight, expandable, and fast and easy to install. Our food safety certifications include HACCP, Global GAO, BRC, ISO22000

"We design our solutions according to the specific needs of our clients. We don’t use ‘plug-and-play technology, as our company is in the country (Kenya, Zimbabwe, Ghana, Rwanda). We have a team of engineers and technicians on standby to install, service, repair and maintain our solutions and all other refrigeration solutions.

For more information: Sharon J Cheboi

Sharon J Cheboi

InspiraFarms Cooling

Phone: +254 700 469 564

Email: scheboi@inspirafarms.com

www.inspirafarms.com