”Our study suggests that Ljusgårda is succeeding in producing lettuce with a lower environmental impact than conventionally imported varieties. It is, however, important to note that our conclusions are context-dependent and cannot be generalized in other regions. We now need to follow up the research to track new findings over time”, says Michael Martin, Senior Researcher and Adjunct Professor of Sustainable Production and Consumption Systems at IVL Swedish Environmental Research Institute and KTH Royal Institute of Technology.

Life cycle assessment research

Recent research carried out at the IVL Swedish Environmental Research Institute and KTH Royal Institute of Technology in Stockholm concludes that the vertical farm of Ljusgårda has a substantially lower environmental impact throughout its production cycle than imported lettuce grown in fields and greenhouses. The results are an important step towards reimagining our food systems.

During 2022, Ljusgårda has been gathering data and working on a full life cycle assessment to compare the environmental footprint of lettuce grown in vertical farms to that grown in fields. The now-published results show that Ljusgårda’s lettuce has a significantly smaller environmental impact than imported field-grown lettuce. The report highlights the success of Ljusgårda’s large-scale vertical farm but still calls attention to points of improvement for the vertical farming industry.

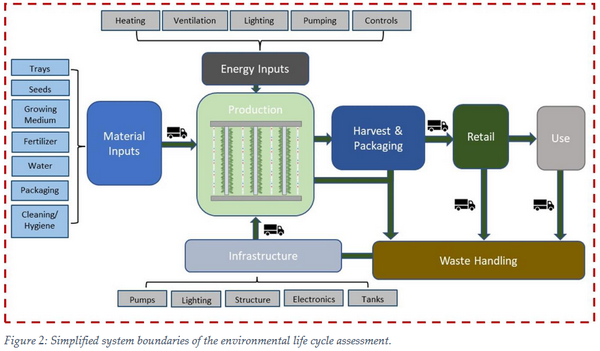

Figure 2: Simplified system boundaries of the environmental life cycle assessment. Click here to zoom in on the photo.

Potential to reduce footprint even more

“We have a lot of potential to reduce our footprint even more, but we need to be looking beyond quick fixes to develop sustainable solutions. By sharing our numbers, we hope to provide good examples and insights,” says Erik Lundgren, Chief Research & Development Officer at Ljusgårda.

”We can’t afford to view industry and nature as opposites. To build a new food system, we need to create closed efficient ecosystems

that can unload the planet. That gives us a framework where we can increase nutrition levels and yield of traditional and novel

produce while decreasing its environmental impact. We call it Bio-Industrial Synergy. The results of this study confirm that we

are definitely doing something right and that technology has a huge part to play in solving our future food systems," says Erik

The company sees the study as a confirmation of its efforts and hopes that it can help shed light on other revolutionary aspects of controlled environment agriculture - such as unlocking the potential for growing plants with much higher amounts of nutrients and vitamins than food available today. Ljusgårda is also looking into introducing nutritious superplants sourced worldwide that haven’t been possible to produce with conventional methods in Europe but are well suited for production within indoor farms.

Optimizing energy use and adding renewables

As Erik explains, one of the key ways of reducing the environmental footprint of vertical farming is by optimizing energy use and striving to use renewable energy. Ultimately, the goal is to reduce the impact per kilogram of lettuce produced. This means growers can reduce their footprint by improving yields with the same resource use, switching to clean energy, and/or reducing overall energy consumption.

“It isn’t just about infrastructure and equipment. It is also driven by yields and reducing our impact per kilogram. We are willing to share information and numbers as the vertical farming industry needs to work together if we all want to succeed,” Erik says.

Read the full report here.

For more information:

For more information:

Erik Lundgren, Chief Research & Development Officer

Ljusgårda - Supernormal Greens

sales@ljusgarda.se

www.supernormalgreens.se