Ensuring food quality and safety have always been top priorities for food retailers, but these concerns are becoming increasingly important for consumers as well. In a recent Emerson study of 1,000 U.S. consumers, 50 percent said they worry about the safety of fresh and frozen foods during transportation to stores. Similarly, half indicated they would be less likely to shop from stores that aren’t using the latest technologies to help ensure supply chain safety. “To meet consumer expectations and protect their brand reputations, grocers need to adopt best practices at every step of the food supply chain,” says Gerd Uitdewilligen with Emerson. “When it comes to perishables, this starts with maintaining strict temperature adherence.”

Ensuring food quality and safety have always been top priorities for food retailers, but these concerns are becoming increasingly important for consumers as well. In a recent Emerson study of 1,000 U.S. consumers, 50 percent said they worry about the safety of fresh and frozen foods during transportation to stores. Similarly, half indicated they would be less likely to shop from stores that aren’t using the latest technologies to help ensure supply chain safety. “To meet consumer expectations and protect their brand reputations, grocers need to adopt best practices at every step of the food supply chain,” says Gerd Uitdewilligen with Emerson. “When it comes to perishables, this starts with maintaining strict temperature adherence.”

Temperature control for quality

“Grocers should establish temperature control initiatives that focus on both food quality and safety,” he mentioned. Temperature control for quality (TCQ) programs are designed to ensure shipping temperatures are kept at precise setpoints throughout the cold chain. If poor temperature control or time-of-harvest conditions cause produce to become too ripe, it will naturally degrade faster or have a shorter shelf life.

Temperature control for safety

Temperature control for safety (TCS) initiatives are mainly concerned with the safe shipping of fresh and frozen produce, meats, seafood, and dairy products. If meat and seafood items thaw and refreeze, they will dry out and lose flavor. If temperatures deviate from safe ranges or become too warm, product will purge (or release water) initially, then begin to grow and spread bacteria.

Preserving perishable food quality and safety requires coordination throughout the supply chain — from inbound harvest and transport to outbound shipping and receipt from distribution centers (DCs). “Grocers should follow a holistic approach that considers best practices at every step of this process.”

- Pre-cool produce after harvest to stabilize produce temperatures prior to loading in refrigerated shipping containers.

- Properly insulate transport reefer trucks and trailers.

- Inspect product between loads to help ensure a clean and contaminant-free space.

- Maintain continuous setpoint temperatures throughout a trip — no fuel saver mode or starting/stopping of refrigeration.

- Calibrate thermistors on reefer trucks and/or trains annually.

- Load pallets correctly to enable proper airflow and consistent temperatures from the front to the back of trailers.

- Monitor load transfer and receipt to ensure refrigerated trailers do not sit in receiving docks for extended durations, especially in warm regions. Trailers are designed to hold (not cool) temperatures, so limit the opening of trailer doors to maintain these holding temperatures.

- Avoid mixed loads that contain a combination of fresh and/or frozen products with different ideal temperature setpoints. This is often done to save fuel costs from DCs to stores but can result in compromising load quality. Consider pallet-level temperature monitoring for maximum temperature assurance.

- Deploy data logging technologies that enable the automatic capture and recording of trip temperatures for reporting and verification purposes.

- Partner with a food safety expert to keep perishables safe and deliver the high-quality food offerings that consumers demand.

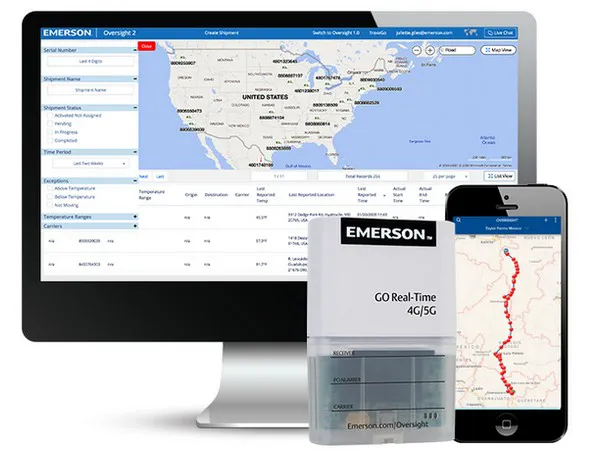

From producers and food retailers to shippers and third-party logistics providers, companies rely on Emerson’s GO real-time trackers and loggers, cloud-based Oversight software and value-added services to help them preserve the integrity of their cold chain shipments. Our integrated solutions deliver detailed temperature and location information on real-time and historic shipments — helping customers to monitor their critical cargo from their points of origin to their final destinations.

For more information:

For more information:

Gerd Uitdewilligen

Director of international sales

Cold Chain Digital Solutions at Emerson

CargoSolutions@Emerson.com

www.emerson.com/cargo