You take out your phone, open an app, and inspect a fruit's quality - sounds futuristic, right? Clarifruit has developed a next-gen, computer vision technology that can do exactly that. This Israeli company has brought the future to fresh produce Quality Control (QC).

"Ours is the world's first automatic QC and data analytics platform," says Elad Mardix, Clarifruit's President. “Anyone in the professional Fresh produce supply chain, from QC inspectors of retailers and wholesalers to, ultimately, farmers, can use this revolutionary app.”

How it works

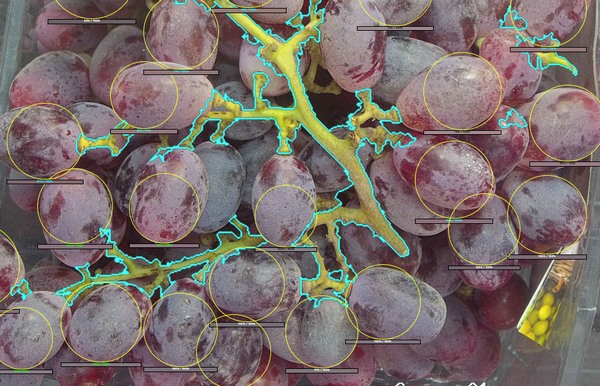

The app’s computer-vision technology currently supports ten of the most common produce varieties. "After the user downloads the app, she can select a category," starts Roman Mirochnik, Calrifruit’s Head of Computer Vision department. A checklist then pops up. You are encouraged to take (at least four) photos of the product in different positions. That ensures the whole fruit is imaged and analyzed. The app automatically detects, for example, external attributes of each berry in a bunch of grapes.

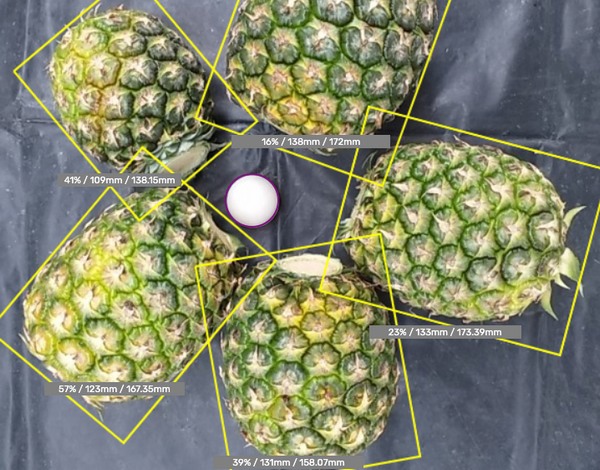

Once uploaded, QC inspectors can see the results in the Management & analytics dashboard almost immediately. It displays measurements like the fruit's size (diameter, length), color (this depends on ripeness), color coverage, and stem condition. "The app, through computer-vision technology and other methods, can gather and configure just about all the data that is important to the user." Measurements can even be added if need be. "That's part of our system's evolution."

Eliminating 'quality mismatching'

The biggest pain-point the supply chain is facing today is 'quality mismatches', as Elad puts it. Differences in quality perceptions from source to receiver lead to rejections, price loss, and wastage. "Our computer vision technology is objective, consistent, and far more accurate than doing QC with the naked eye."

The system logs everything, like where, when, for how long, and by whom the fruit was photographed. "You can see everything in the auto-generated QC report," says Roman. "You no longer have to rely on quality controllers' subjective judgment," adds Elad. How big is the margin of variance? "We tested this extensively. On average, we’ve seen human inspectors have about a 13% difference in results, between each other. When we did the same inspections with Clarifruit’s computer-vision technology, that variance came down to five percent."

Clarifruit's goal isn't, however, to be 100% accurate. "Our goal is to be at least as good as human inspectors in whatever set-up. We're probably going to be much better. We already are. And this has so many benefits. We're not trying to reinvent the QC process. We're simply automating the process. We're completely changing the game in terms of how the QC process is being performed," concludes Elad.

Artificial Intelligence (AI)

This system uses AI. But, how is AI applied to the Fresh Produce industry? "AI and machine learning are the processes in which you train a computer to perform specific tasks," Roman explains.

"In our case, that's using an image to identify fruits' attributes, defects, and other details. Then we can take all the measurements. This all involves AI algorithms. These algorithms are all based on data and training." It's a laborious, complicated task.

"We take hundreds of thousands of images. We label each one with the information the computer is supposed to extract from the image. Eventually, the algorithm uses all this extracted data and applies it to other images." Roman says this is an ongoing process, but Clarifruit’s cumulative expertise is starting to pay off. “Our AI-driven platform already knows what attributes should be collected for each produce using pre-configured settings and AI based models. While some of those attributes, such as measuring the exact color in various lighting conditions, are complex and time consuming to analyze, we have automated all of those efforts on our platform. We aim to enable our customers to inspect quality in any condition, whether it is out at the fields during pre-harvest or inside the distribution center. “, says Roman.

Continuous improvement

As phone and imaging technology advance, so will the Clarifruit app. The system is constantly being updated in several ways. "First, the produce categories. We began with two categories 2 years ago; we now have ten. We plan to double it by the end of the year, and likely end up with up to 40 categories eventually."

Clarifruit's computer-vision features and analytic capabilities are also progressing. "Automatic defect identification is one of the features that's still in development. Many types of defects can reduce a produce’s quality grade in different ways." The company wants to help users take the best photos possible, so it wants to expand its web applications too.

Elad emphasizes they are laser-focused on making the mobile app experience extremely user-friendly. "We've improved the app so now it guides users. It gives real-time advice for those of us that are less tech-savvy. People will be comfortable enough to take high-quality images."

Roman says it was easier to teach the AI how to identify and extract the measures from the more uniformly-shaped fruits. But they don't exclude any produce. They already have pineapples and bananas in their produce portfolio. "We plan to expand to additional produce categories, such as strawberries and peppers."

Market opportunity

"We're targeting the entire professional supply chain," says Elad. He views the supply chain as having four key segments - growers, marketing companies, wholesalers, and retailers. Clarifruit began developing its platform with some of the world’s leading marketing companies two years ago. That was a deliberate decision. "Over the last six months, we’ve expanded to include wholesalers and, specifically, retailers."

Elad reckons retailers will likely become their top clients. "They have the broadest Fresh Produce portfolio and scale and therefore, perform most QC inspections along the supply chain." He hopes that in two to three years from now, Clarifruit will have an established sales presence in most parts of the world, including online.

"We have only begun to scratch the surface of what’s possible with automatic, cloud-based QC, and I expect our platform to expand the availability of high-quality QC to the entire supply chain, including growers and online marketplaces who currently lack those capabilities”.

For more information:

Elad Mardix

Clarifruit

Tel: +(972) 543-666838

Email: elad@clarifruit.com

www.clarifruit.com

www.clarifruit.com/start-for-free/