Using an automatic peeler machine to replace manual peeling is a common trend. There are many types of peelers in the market, and although they all serve the same peeling purpose, the functionality, productivity and results can be very different. ASTRA Inc. is an innovative Japanese peeler developer. The company is famous for its unique ‘Peeler blade’ technology. The sales manager Ryo Takeshita explained how the peeler blade works and introduced us to its advantages.

Multiple types of fruits and veggies can be peeled with ‘Blader Peeler’

Multiple types of fruits and veggies can be peeled with ‘Blader Peeler’

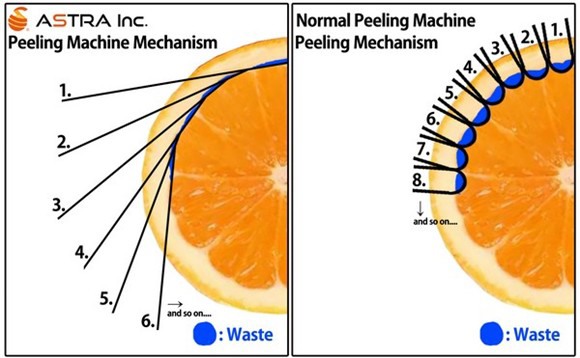

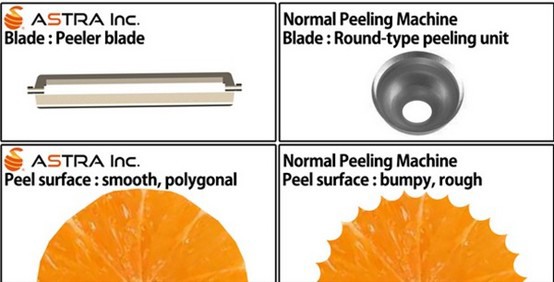

“When peeling fruits with your hand, you will always use a hand peeler. Hand peelers can always peel beautifully. However, most of the traditional peeling machines don’t use the same blade of the hand peeler, they use a ‘round-type peeling unit’. This peeling unit cuts out small circular pieces around the edge until the fruit is peeled. Though the round-type peeler serves basic functionality, it can result in high waste.” Ryo said. “To solve this issue, ASTRA developed a ‘blade peeler’. The principle shares similarities with manual peeling. The blade is straight, sharp and thin. When turning, the blade moves in a polygonal way, while always tightly pressed to the surface of the fruit. ASTRA is one of the very few companies who can manufacture peeling machines using this technology.”

Less waste and smoother appearance from ASTRA ‘Peeler blade’

Less waste and smoother appearance from ASTRA ‘Peeler blade’

Better peeling performance

Compared with traditional ‘round-type peelers’, the new ASTRA ‘blade peeler’ generates a variety of benefits with regards to peeling performance. “First of all, the fruits’ peeling surface is much smoother (than round-type peelers, which leave the pulp surface very bumpy and rough). This results in low pulp waste and fewer juice drippings. Also because of the smoother surface, the fruit has a longer shelf life and can keep fresh for a longer period. Secondly, the straight blade performs faster with high accuracy, which results in better yield rate.” Ryo said. “Most importantly, users can easily adjust the peeling depth and select the most suitable program for a certain type of fruit. No matter how thick or thin the fruit peel is, from thick-skinned oranges to thin-skinned lemons, the blade peeler will provide the best performance accordingly.”

Comparison between ASTRA ’Peeler blade’ and traditional peeler machine

Comparison between ASTRA ’Peeler blade’ and traditional peeler machine

One machine serves multiple types of fruits

Benefited by the blade peeler, a wide range of fruits and veggies with various features can be processed with the ASTRA peeler. Ryo listed a few examples:

- Irregularly shaped fruits (Mangoes Video)

The irregular fruit shape challenges the peeling technique. Mangoes share the reputation of ‘most difficult fruit to be peeled’. Every mango can be different, from round to elongated shape. The highly-flexible blade peeler works perfectly on each fruit.

- Thick skin fruit (Pineapple Video)

Fruits such as pineapple have a barrel shape. A traditional round-type peeler can easily result in high waste. As the blade peeler moves in a polygonal way, the yield rate can be 50% higher than a round-type peeler.

- Thin skin fruits (Lemons Video)

Sometimes you only need thin fruit skin for lemons and limes, when making drinks like Limoncello. Zesting can be done with the adjustable- depth blade, the thinnest fruit skin can be perfectly peeled!

- Smooth skin products (Onion Video)

The skin of the onion is so smooth that a normal blade may slip on the surface, or even if it peels, the skin gets stuck to the blade. But the blade peeler even makes onion peeling possible.

- Small size fruits (Kiwis Video)

Restaurants and fruit-salad companies often pursue high productivity, which leads to high requirements when processing small-size fruits. The high-speed blade peeler already proved its performance in several kiwi factories in New Zeeland.

Peeling irregular-shaped fruits

Peeling irregular-shaped fruits

Why unique?

When asked why the blade peeler has so many advantages, but the round-type peeler is still the mainstream in the market, Ryo told us, “peeling seems a simple performance, but it is the combination and balance of many elements such as the material of the blade (the metal used for some blades can only be produced in Japan), the shape of the peeler, the way it touches the fruit and the way it moves and speed control, etc. - all these factors play a role, and interact with each other. The technological improvement behind the blade peeler is more than a simple change of the form of the blade.”

ASTRA was nominated as the winner at the "Kitchen Innovations Award" in 2018. (CEO Hirotaka Ichijo at the middle)

ASTRA was nominated as the winner at the "Kitchen Innovations Award" in 2018. (CEO Hirotaka Ichijo at the middle)

Over the past 20 years, ASTRA has been fully dedicated to automatic peeler innovation. The company has been granted several awards related to automatic peeling technologies, including the ‘Kitchen Innovations Award’ in 2018, ‘Touhoku New Business Award’ in 2019, and the ‘14th Nippon New Business Creation Award for Entrepreneurial Excellence’ in December 2019. “All the patents and awards are in recognition of our sincere efforts in innovation. We are proud to say that all of these technologies were born out of countless failures and ideas that were put into storage.” Ryo said.

More information:

ASTRA Inc.

Mr Ryo Takeshita

Tel.: +81 0245412444

E-mail: ryo@e-astra.co.jp

Website: https://peel-a-ton.com/