Being able to predict chilling damage could be a powerful decision making tool for Australian lemon growers wanting to export to overseas markets. New research from the Queensland Department of Agriculture and Fisheries suggests there is potential for Near Infra-Red (NIR) cameras to grade out fruit unable to withstand export handling.

Queensland lemon shipments to Asian markets are required to follow in-transit cold disinfestation protocols. Protocols vary between countries, but typically involve prolonged cold storage in-transit of 14-21 days at 1-3.1°C. While the fruit generally tolerate these conditions, skin damage consistent with chilling injury is occasionally encountered and results in significant economic and reputational loss.

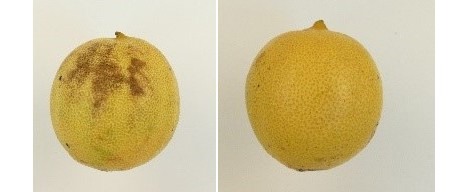

Chilling injury is typically characterised by pitting and sunken lesions on the surface of the fruit following exposure to low, non-freezing temperatures (Figure 1). Previous research has shown that sensitivity to chilling damage can differ between farms, seasons and varieties; however, it remains unpredictable and difficult to manage.

Figure 1: Typical chilling injury symptoms include sunken dark lesions versus non chilling fruit

Dr Hung Duong’s latest work found hyperspectral imaging can detect and predict chilling injury in lemons before it is visible to the human eye. Scanners correctly predicted chilling injury on 70% of fruit after de-greening and cold storage. This technology could allow fruit of lower robustness be graded out and sent to the domestic market only where it is not subjected to chilling temperatures during transport.

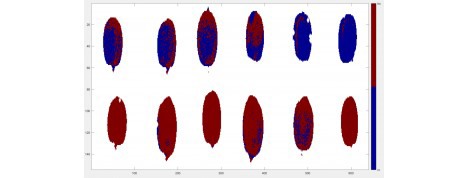

Fruit were scanned within 3 hours of harvest, after de-greening and after cold storage using three different hyperspectral devices (Bruker Matrix-F, Pika NIR 320 and Pika XC2) at wavelengths of 830-2500 nm, 900-1700 nm and 400-1000 nm, respectively. Various statistical models were applied to the data in order to analyse results (Figure 2).

Figure 2: An example of the model predicting chilling injury. Brown pixels predict no chilling damage, blue pixels show where chilling damage is likely to occur.

“Chilling injury is hands down the number one challenge for me in exporting my lemons”, says Wim VanNiekerk, Director of Widem Farming in Dimbulah, North Queensland. “Being able to grade out fruit with higher risk of chilling injury is a huge business advantage, as well as limiting the chances of any quality disputes and unhappy clients when my product arrives overseas”.

Similar technology has been used in cucumber, green bell pepper and apples to correctly identify skin defects before symptoms are visible. More research with lemons is required to refine the modelling before practical adoption of the technique is explored. Nonetheless, the results in lemons so far are promising and have great potential to assist the expanding Australian lemon industry.

Acknowledgements: This research was funded by Agri-Science Queensland Innovation Opportunity – Department of Agriculture and Fisheries, Queensland (DAF). Thanks to the project team; Carole Wright, Brett Wedding, Andrew Macnish, Ebony Faichney & Widem Farming.

For more information:

Hung Duong

Email: hung.duong@daf.qld.gov.au