Technical benefits of fresh fruit post-harvest treatments have been scientifically demonstrated and established during last decades and it is fully accepted that they deliver very relevant and positive additional functionalities than can be summarised as follows:

I. reducing permeability to water loss

II. creation of a modified atmosphere for coated fresh produce and effect on ripening

III. retardation of weight loss and surface desiccation

IV. maintaining original structural integrity

V. replacing/recovering of the surface natural wax lost during cleaning and sanitation after harvest.

VI. reducing decay

Coatings in general are primarily applied to fresh fruits to increase their postharvest life by regulating the exchange of water and gases (oxygen and carbon dioxide). This primary function allows for less weight loss during storage and, in some cases, the alleviation of some postharvest physiological disorders such as chilling injury or rind breakdown. In addition, coatings can also provide shine and gloss to improve the fruit’s external appearance.

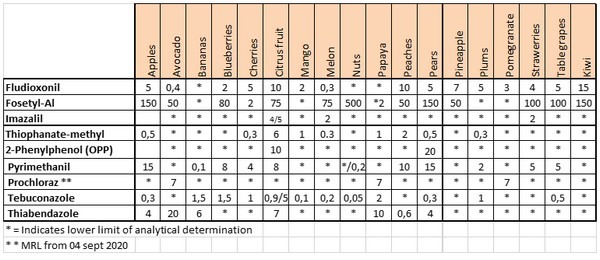

Active substances and MRL approved for postharvest treatments on fruits in the EU. Non exhaustive list. Please refer to Regulation 396/2005 to confirm MRL mg/Kg

Click here to enlarge the table

Within the different types of coatings, edible coating are well known.The idea of using edible coatings has been obtained from studying the characteristics of the skin of fruits and vegetables (Goldstein et al., 1992). These are a thin layer of edible materials which restrict loss of water, oxygen and other soluble material of food (Bourtoom, 2008).

The coating is an integral part of the food which can be eaten as a part of the whole food product (McHugh and Krochta, 1994). Edible coatings can offer the following advantages to the fresh fruits and vegetables industry: a) improved retention of colour, acids, sugar and flavour components; b) maintenance of quality during shipping and storage; c) reduction of storage disorders; and d) improved consumer attraction (Nisperos-Carriedo et al., 1991).

During the last few decades, since 1980 approximately, a range of formulations of edible coating have been developed which are widely used nowadays in fruits and vegetable industries being behind them a mature, developed and proven technology (Citrosol AK BIO, NATURCOVER, Teycer, GREENSEAL, FOODWAX, …)

But, in some cases, edible coatings are not successful. The success of edible coatings for fresh products totally depends on the control of internal gas composition. Quality criteria for fruits and vegetables coated with edible films must be determined carefully and the quality parameters must be monitored throughout the storage period. Color change, firmness loss, ethanol fermentation, decay ratio and weight loss of edible film coated fruits need to be monitored.

The incorporation of specific approved fungicides on coating formulations for post-harvest treatments (plant protection products) is a must when a decay control is required, as for example on citrus fruits, since this type of fruits are very prone to decay when no post-harvest treatments are applied.

Of course, those fungicides must be approved by the regulatory authorities as those approvals are synonym of a safe use.

Post-harvest treatments to increase shelf life and to reduce food losses are available for both organic and non-organic production of fruit and vegetables. When used, they must be authorized by the producing country and the country of destination.

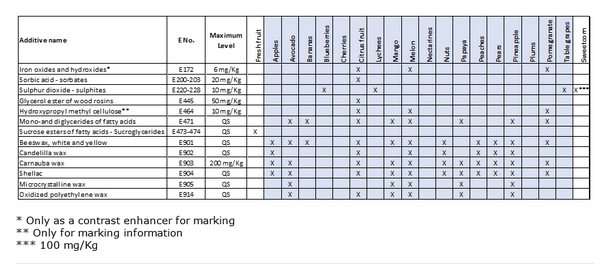

Food additves approved for postharvest treatments on fruits and vegetables in the EU. Non exhaustive list. Please refer to Regulation 1333/2008 to confirm authorised use and maximum level (04.1.1 Entire fresh fruit and vegetables)

Click here to enlarge the table

All those benefits of post-harvest treatments lead to increased shelf-life of the fresh fruits and contribute to reduce food losses along the food supply chain, being this contribution perfectly aligned with the aim of the FAO and UNECE initiatives for reducing food losses and waste (UNECE. Code of Good Practice - Reducing food loss in handling fruit and vegetables. 2019).

As additional information a list of authorised active substances in the EU for postharvest treatments on different fruits and their MRLs is given on Annex 1 and a list of authorised food additives in the EU on different fruits and their maximum levels is given on Annex 2.

References:

1) Bourtoom T. 2008. Review Article: Edible films and coatings: characteristics and properties. Int. Food Res. J. 153: 237-248.

2) Goldstein J.L., Newbury D.E., Echlin P., Joy D.C., Romig A.D., Lyman C.E., Fiori C., Lifshin E. 1992. Scanning Electron Microscopy and X-Ray Microanalysis, 2ed New York: A Division of Plenum Publishing Corporation, pp. 571-599.

3) Kabir, J. & Kore, Vijay kumar & Tawade, Sima. (2016). Application of Edible Coatings on Fruits and Vegetables. "Imperial Journal of Interdisciplinary Research (IJIR). 3. 591-603.

4) McHugh T.H., Krochta J.M. 1994. Milk protein based edible films. Food Technol. 481: 97-107.

5) Nisperos-Carriedo M.O., Baldwin E.A., Shaw P.E. 1991. Development of an edible coating for extending postharvest life of selected fruits and vegetables. Proc. of the Florida State Horticultural Society, 104: 122-125.

6) Vargas M., Chiralt A., Albors A., González-Martínez C. 2008. Effect of chitosan-based edible coatings applied by vacuum impregnation on quality preservation of fresh-cut carrot. Postharvest Biol. Technol. 512: 263-271.

7) UNECE. Code of Good Practice - Reducing food loss in handling fruit and vegetables. 2019. https://www.unece.org/trade/agr/unece-foodlosschallenge.html

For more information:

Agrupación Española de Servicios y Procesos Postcosecha

AGRUPOST

Plaza Alfonso el Magnánimo, 14-3º-4ª

46003 – Valencia. España

info@agrupost.es