The removal of CIPC next season has pushed the burden onto other tools in the box. However, how cost effective these treatments are at current market prices is a question on many people’s mind.

The removal of CIPC next season has pushed the burden onto other tools in the box. However, how cost effective these treatments are at current market prices is a question on many people’s mind.

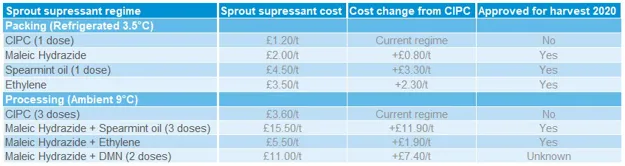

We have estimated a total storage cost per tonne for different sprout suppressant regimes over an 8-month period. The table below displays the estimated costs for the different regimes, these have then been added to industry costings from the AHDB Potato Storage calculator to give the total cost.

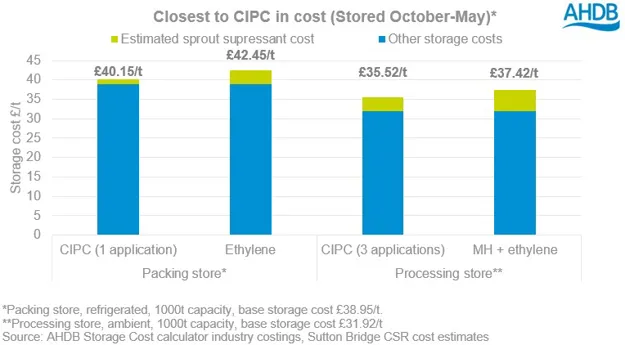

For refrigerated stores the base cost (excluding sprout suppression) over an 8-month storage period is estimated at £38.95/t and for ambient stores this figure is £31.92/t.

Ethylene

On a price basis, ethylene appears to provide the best alternative to CIPC. Our estimated storage costs come in at 5-6% more than the current CIPC regimes. However, the impact on crops can vary based on the variety stored. In some variety’s ethylene can darken fry colour, making it unsuitable to use on some processing crops.

In other varieties ethylene simply does not inhibit sprout growth to a sufficient degree for it to be viable. As such, while it is a cost-effective alternative, variety selection is particularly important if you are planning to use ethylene in store.

Spearmint oil

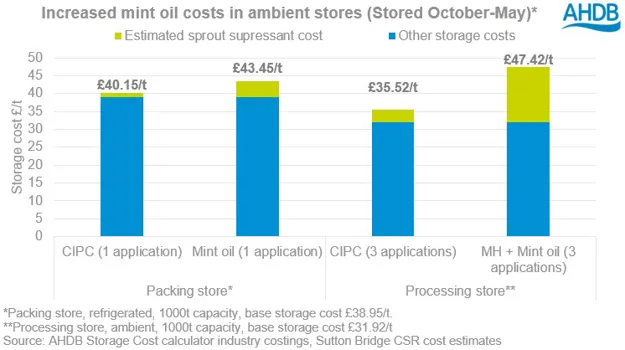

Spearmint oil has been used in the packing sector for some time (approval in 2012) with a proven track record of effective sprout suppression. The total storage cost for one application in a fridge store is just over 8% higher than the equivalent CIPC treatment.

However, for processing, in ambient stores, costs may increase, with more applications of mint oil needed to control sprouting effectively. As such, an application of MH and 3 applications of spearmint oil, over an 8 month storage period, results in an estimated total storage cost of £47.42/t.

Although mint oil has a strong natural odour, with an appropriate delay between treatment and unloading from store, processors have found no significant evidence of taint in the finished product, and most are willing to accept mint oil treated potatoes. Commercial scale trials of crops destined for the processing sector are on-going.

1,4-dimethylnaphthalene (DMN)

DMN is an effective sprout suppressant. However, currently the product is not registered in the UK despite having approval in some European countries.

The cost compared with CIPC is higher. For an ambient store two applications of DMN and one application of MH results in an estimated total storage cost of £42.92/t over an 8-month storage period.

Precautions are needed to control losses of the very volatile chemical from stores after treatment.

Store management

All of the post-harvest applied chemical suppressants share one thing in common: they are more volatile than CIPC and so are more easily lost from store. This increases costs and will require work to be done to seal stores better.

Some changes to management of stores will also be needed, for example, more precise use of ambient air. This will affect both temperature control and flushing of respiration products such as carbon dioxide, but a balance will need to be struck to ensure chemical control is not compromised.

It is prudent to check the requirements of your end customer and supply chain before using a new sprout suppressant in your stores.

Costs keep going up…

Sprout suppressant costs look set to increase for the season ahead. Given continued uncertainty over availability and management of alternatives to CIPC, there are questions over the value of storing crops for delivery in the last few months of next season, with many growers citing little current incentive to store longer term without an increase from current rates to offset the higher risks of keeping crops until May, June or July.