The Anjari family business, located in San Esteban (Chile), one of the main fruit growing areas of the country, exports its products to five continents. Founded in 1990, it pioneered the drying of raisins and it now produces 16,000 tons a year. Its growth and its demand for product quality have led to the acquisition of Tomra's Helius 1600 free fall sorter, which guarantees the selection of defect-free products and is the machine with the highest processing capacity installed in the raisins manufacturing industry.

The Chilean company already has two other Tomra, IXUS detectors (models 570 and 800), which use X-ray technology to detect and eliminate foreign elements (metals, glass, stones, high-density plastics, etc.) from the product.

The Chilean company already has two other Tomra, IXUS detectors (models 570 and 800), which use X-ray technology to detect and eliminate foreign elements (metals, glass, stones, high-density plastics, etc.) from the product.

Anjari uses the Thompson grape variety, which is elongated and slightly bittersweet, and the Flame variety, which is round and very sweet and is the grape that gives Chile its popularity in the raisin sector. After a first washing process, the raisins pass to the first Tomra detection equipment that has several types of laser: the Helius 1600. This equipment also has different programs depending on the type of raisins being packaged and allows the elimination (by detecting the difference in both color and structure) of all foreign matter. Once the boxes are packaged and sealed, they go through two additional metal detector devices.

“Thanks to the installation of the new sorter, we have been able to increase production yields and reduce waste, as it is very accurate. The IXUS, on the other hand, is a very useful tool to eliminate elements of a different density than that of raisins and are highly effective with stones of various sizes,” stated Rene Anjari, the owner and founder of the company.

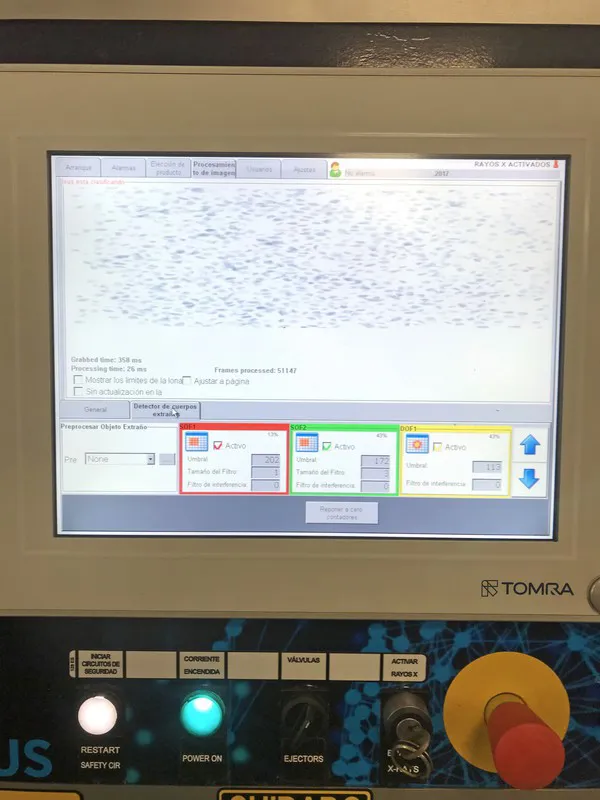

The Helius 1600 ensures the final product has an excellent quality, without unwanted discolorations or foreign materials. Its ejector valves reject defects in milliseconds; its small system barely takes up space; Quality control and comments can be accessed through a very intuitive touch screen; It has a modular and upgradeable design; provides different types of laser technologies adapted to the use that is needed; and it can be synchronized between lows and have high capacities. It also has an effective expulsion system and its accuracy is constant, guaranteeing a very low false rejection. In addition, it has a long service life, as well as a high capacity, which reaches 8 or 10 tons per hour.

For more information: www.tomra.com/es-es