Timber isn’t plentiful in South Africa – but discarded plastic bottles are, and a Cape Town-based firm is making the leap to fruit pallets constructed from recycled PET plastic, employing their proprietary injection mould and Portuguese manufactured tooling.

During the recent Cape drought the sheer amount of discarded plastic bottles, particularly water bottles, caught the attention of Christopher Smith, director at PalletPlast.

During the recent Cape drought the sheer amount of discarded plastic bottles, particularly water bottles, caught the attention of Christopher Smith, director at PalletPlast.

It led to the idea of giving use to this often landfilled type of plastic, shunned by many recyclers (especially coloured PET bottles) at the same time as wooden fruit pallets are climbing in price in the Western Cape. Now they remove 400 tonnes of plastic from the waste stream every month (right: plastic flakes to be turned into a pallet).

South Africa’s annual demand for pallets, across all industries, are in the region of 30 to 40 million units, creating an exciting opportunity in the fruit industry for a sustainable pallet with excellent phytosanitary properties and reliable strength, he says.

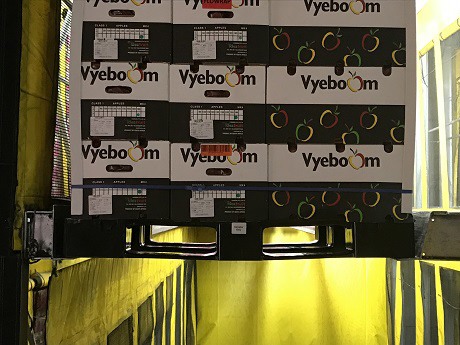

Their plastic pallets have a racking capability of 1.2 tonnes. The only virgin plastic on the pallets are the three straps across the length, slightly wider than usual, that act as pre-cast beams, much reducing the possibility of collapse of pallets holding heavy fruit like citrus or apples.

Cheap packaging material puts top class produce at risk

“It’s fascinating that producers spend years on selecting cultivars and perfecting the cultivation and appearance of the fruit, and then they buy the cheapest possible packaging material,” Christopher says. He notes that plastic pallets are less prone to damage by forklifts than wooden pallets.

The company spent years on R&D, sending their prototypes to Portugal for moulding, and then running trials with Tesco and the postharvest research teams within the local fruit industry. The company has been producing their pallets for ten months now.

The company spent years on R&D, sending their prototypes to Portugal for moulding, and then running trials with Tesco and the postharvest research teams within the local fruit industry. The company has been producing their pallets for ten months now.

“We’ve seen interest from some of the forward thinkers with large volumes in the fruit industry. It does require them to negotiate with their buyers and to make their buyers aware that these pallets can be recycled.”

Currently South African wooden fruit pallets, made of local pine or eucalyptus wood, are usually incinerated in biomass furnaces on arrival. A PalletPlast pallet can be fed into a granulator and re-enter the plastic value stream.

Best racking capability at its price point

A recent road show in the Southern Cape has demonstrated the unanimous enthusiasm for their pallets in the industry.

“At its price point, PalletPlast pallets have the best racking capability, it’s less flammable with better phytosanitary properties and the product looks better when it arrives. It's the cheapest plastic pallet on the market for what it does.”

He also notes that these pallets are lighter (16.5kg) than wooden pallets, which could present an air freight solution.

“We are not in the single-use plastics arena, we focus on plastic with multiple uses and the circular economy,” Christopher notes, who used to be in the turf industry before, maintaining Sun City’s famous golf courses. “Recyclability and design for recycling are the ways of the future.”

For more information: Christopher Smith

Christopher Smith

PalletPlast

Tel: +27 087 150 7336

Email: Christopher.smith@palletplast.co.za

http://palletplast.co.za/