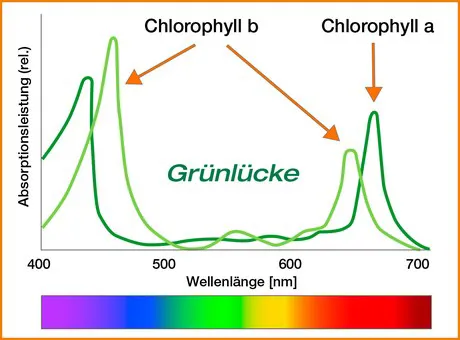

During storage and processing, the toxins solanin and chaconin are formed within the potatoes. These are responsible for the "greening" of the potato. This makes the tubers not only unsightly and unsuitable for the trade, but inedible as well, because the glycoalkaloids solanine and chaconin are toxic to humans. Based on various studies and experience, Conpower has been manufacturing special luminaires for the potato industry for nearly a year, selecting LED diodes that work in the 530 to 540 nm light spectrum.

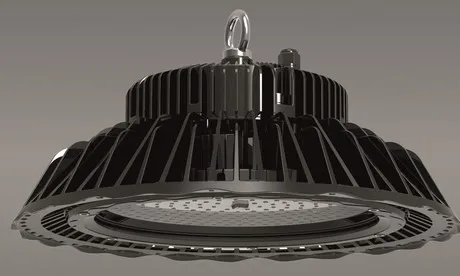

Green LED-Lamp 'Helios'

Green LED-Lamp 'Korona'

Good results

The "green LED light" prevents greening and the formation of toxins within the potato; a decisive factor for storage and processing of the potato. Thanks to the high light efficiency of the Conpower LED luminaires of up to 145 lm/W and a control technology adapted to the operating procedures, energy savings of 70 to 80 percent are being achieved.

In various publications, the VSD (Experimental Station Dethlingen) also points out that solinin formation is prevented by "green light" (Newsletter Nov. 2007, May 2018). By further developing the coating of diodes, it is now possible to precisely limit and measure the spectral range, says Christian Vendt, the company's sales manager. "Selecting diodes that emit light precisely in this spectral range and building in rugged luminaires for industrial use is our strength, and we are taking advantage of this development to optimize our luminaires for use in potato storage."

A potato warehouse with 'normal' lighting.

A potato warehouse with LED lighting system.

Solanin danger along the whole supply chain

With the new process, lighting is no longer a time limiting factor in potato logistics. Young potatoes in particular are already in trouble after a lighting period of only four hours, which makes them start to form solanine. That means that a potato can already be subjected to too much light whilst just going through the harvesting, cleaning and packaging process, explains Vendt.

Markus Schrenk and Christian Vendt of CONPOWER GmbH & Co.

In view of the clear added value of the procedure, the solutions are not profitable beyond a specific company size, according to Vendt. The need for illumination grows linearly with the area of operation, so the sales manager sees potential in both the smaller and larger service providers around the potato.

"Any company that openly exposes potatoes to more than four hours of daylight or artificial light can sustainably improve product quality with the help of our luminaires." Recent project inquiries come mainly from Germany, France, Italy and Greece, but we saw a particular sensitivity to the potato quality in the Netherlands," says Vendt.

Green LED light inhibits the solanine formation in the potato and thus the germination of the tuber. In the course of this, the storage quality of the potato is significantly improved.

Green LED light inhibits the solanine formation in the potato and thus the germination of the tuber. In the course of this, the storage quality of the potato is significantly improved.

Potential up to the POS

So far, the most important target groups are interested in processing, industry and logistics. Greece is currently running a project with a chip manufacturer, informs Vendt. "We have recently become a member of the German Potato Trade Association (DKHV) and also see an interesting development area in the retail sector: the potatoes are available in the food retailing and at the POS and the quality suffers under these conditions, so our luminaires could also help here."

Visit the company at the Weuthen Potato Day (August 29th in Schwalmtal) in the central tent or at Potato Europe (4th & 5th September in Kain, Belgium).

For more information:

CONPOWER Betrieb GmbH & Co. KG

Semmelweisstr. 8

82152 Planegg

Tel: +49 89 416 1488 - 70

Fax: +49 89 416 1488 - 71

e-Mail: betrieb@conpower.de

Internet: www.conpower.de