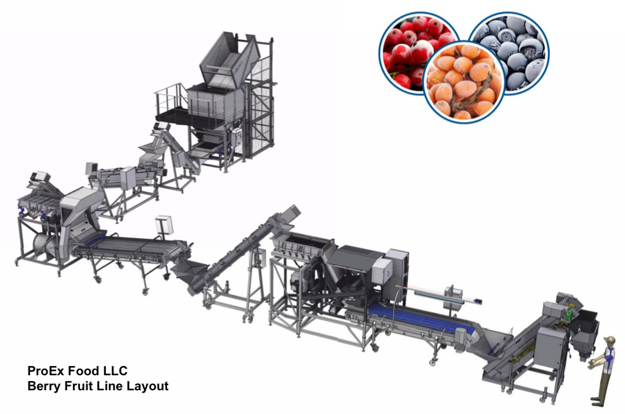

"We want to offer our customers a complete solution for IQF berries - from washing on arrival to packaging," says Daniel Ghadiri of ProexFood LLC. "When we receive a customer request, we use pictures and samples to see exactly what the demands are that are being made on our machines, depending on the product."

In general, the process after the IQF freezer begins with a cleaning that may vary from berry to berry, according to the expert. As an example, he names blueberries: With specific air cleaners, foreign objects will be removed. But this step can also be used to sort berries by weight - depending on the calibration of the plant. In addition, there is an additional step that is meant to polish the berries: "This has two distinct purposes: removing any leaves that may possibly still be attached to the berry and improving the accuracy of the optical sorter that follows in the next section. And of course, the finished product simply looks nicer."

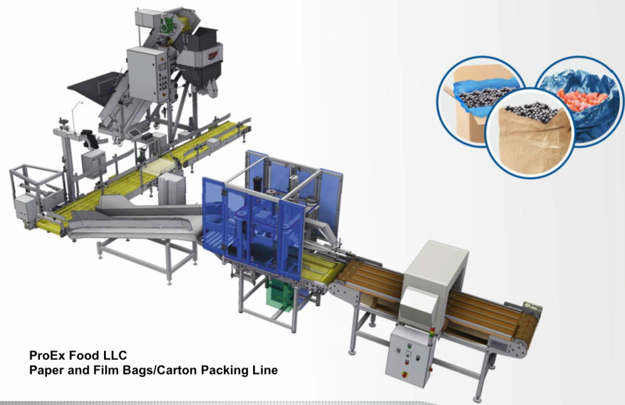

For optical sorting, ProexFood integrates other companies' solutions: "We do not offer optical sorting systems ourselves, but work closely with our partners to provide the best opportunities for our customers." After sorting, there is a manual inspection line to make sure that the product reaches the consumer in optimal condition. "Depending on the customer's wishes, the berries can be packed afterwards. Some companies send the goods in bulk packaging to special packing houses, others pack the berries already in their final packaging, we can respond to both."

The processes continue to vary between the berries: "The berry polishing is of course better for fruits with a smooth shell, such as blueberries, while raspberries are very delicate fruits that are frozen before inspection and sorting to better maintain the structure. "

"There are not many companies that offer real complete solutions from a single source, so we want to stand out from the competition. We put a lot of emphasis on turnkey equipment, and in the US we even have projects where we even design and construct the buildings in which our machines are going to be placed," says Ghadiri. "We design the concept and our construction industry partners take care of the rest." Currently, this service is only an option in the United States.

The complete solutions are suitable for a variety of fruits, including blueberries, cranberries, sea buckthorn, cranberries, elderberries, rowan berries, currants and aronia.

ProexFood is now represented in many countries worldwide. Companies in the US, Australia and throughout Europe, including countries such as Hungary, France, Germany, the UK, the Netherlands and Switzerland, use the processing and packaging lines. The companies are supported by an extensive network of employees of the companies in the countries and the company headquarters in Dusseldorf, Chicago and Milwaukee.

For more information:Daniel Ghadiri (Europe, Middle East, Asia)

ProexFood LLC

ProexFood LLCTel: +49 151 57881362

E-Mail: dan@proexfood.com

Ross Lund (North and South America, Australia)

Tel: +1 (262) 215-5991

E-Mail: rosslund@proexfood.com

Webseite: www.proexfood.com