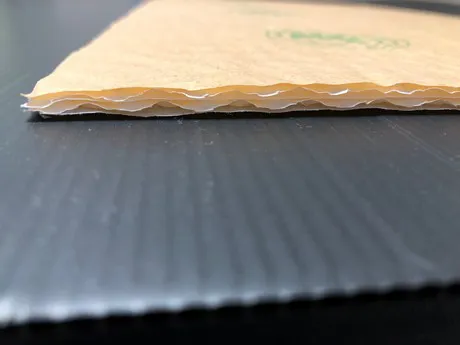

It has been two years since the company Deltapack France started to specialize in the fruit and vegetable sector. Michel Guerid, manager of the company, explains that this new orientation was born of a real need expressed by the professionals of the sector. “We saw that the packaging of fruits and vegetables needed to be modernized on the export market, and we had just the right product exporters were looking for.” This product is the Delta Pad 5, a technical kraft paper composed of 5 layers of smooth and embossed paper forming an airy cushion, usually found in boxes in the confectionery sector, and also adapted for the export of apples, for instance.

The Delta Pad 5

The Delta Pad 5

Technical qualities adapted to maritime transport conditions

In order to resist the harsh conditions of transport by boat, Michel explains that the paper must be of impeccable quality. “It is often very cold on the boats (temperatures can reach 2°C) and humid (up to 75% humidity). The journeys can also last very long. Therefore, the paper must present certain technical characteristics in order to make it through journeys of sometimes 45 days, and be in its original state upon arrival. Our product is resistant to humidity and its embossed appearance makes it look like an air mattress that always regains its original shape. It isolates from variations in temperatures and from vibrations. The pure cellulose gives it stability and make it indifferent to external influences. And of course, the Delta Pad 5 is compatible with biological agriculture.”

Besides, being composed of pure cellulose, ink and food glue, the paper is recyclable, compostable and biodegradable.

This packaging is already being used by the chocolate industry, in direct contact with the product itself. Therefore, it meets the requirements of the sanitary standards of the agrofood industry. “Our products are registered. We have all the official certifications and food guarantees allowing us to offer it to professionals.”

About Deltapack France

The company has existed since 1995. “We are factory agents. We are part of a group of a dozen paper mills, specialized in different types of technical papers.” In fact, the company covers several business sectors: the automobile industry, the construction sector (with the manufacture of a bituminous paper used to keep terraces waterproof), the agrofood sector (with interlayers of protective pallets, waterproof closures of pet Food bags), or even the breeding industry (transporting 1-day-old baby chicks).

In the fruit and vegetable sector, Deltapack France works with national distributors. “In France, distribution was entrusted to the group l’Univers de l’Emballage, which has 5 branches. They distribute products all over France and are at the heart of the fruit industry. We manage the manufacture, logistics and quality control.”

Great success at Fruit Logistica

Michel claims that despite their tiny stand at the Fruit Logistica fair, the company and its new products were a great success. “If you knew the number of professionals who were interested in our products! In fact, we have already shipped many pads since the fair in Berlin. One of our characteristics that really seduced professionals are our very short delivery times. The products are usually received within only 15 days after the order has been placed,” explains Michel. “Another appealing aspect is the fact that our cushion pads can be placed automatically in the crates. Packaging specialists immediately saw the benefit of automating the placement of the pads with suction cups to save money.”

The DeltaPack team at Fruit Logistica

The DeltaPack team at Fruit Logistica

For more information:

Michel Guerid

Deltapack FRANCE

Parc du Roubian

3 rue des charretiers

13150 Tarascon

+33 490 491 300

Michel.guerid@gmail.com

http://www.deltapack.eu/fr

L’Univers de l’Emballage

info@univers-emballage.com

www.univers-emballage.com