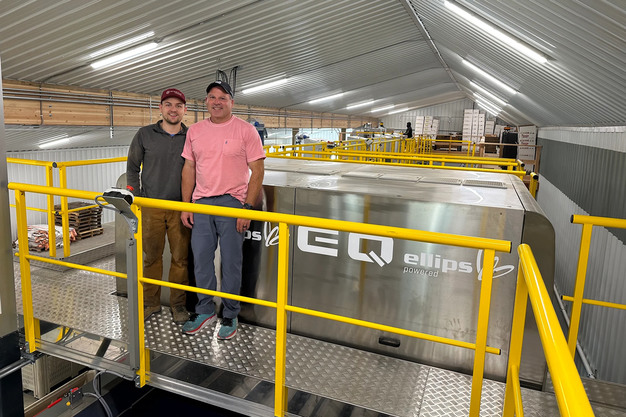

Pioneer Potatoes is a relatively small family farm in the Skagit Valley of Washington state. "We're a sixth-generation farm specializing in potato growing, packing, and shipping for the past 25 years. However, our farming legacy spans over 150 years, including various other produce. Although we may not grow as many acres as our neighbors in the Skagit Valley, we are focused growing and packing the highest quality from the acres we have. We can't supplement our revenues with quantities. What we grow must be great. We don't have that extra 100 acres to say, "we will get the quality eventually". Or "we will get the right sizes with volumes". We are maximizing what we are doing, providing great quality and good size", says Wylie Thulen.

Is it profitable for a relatively small farmer to invest in optical grading technology?

Pioneer Potatoes understands the fundamentals of effectiveness and efficiency in grading and provisioning potatoes. Despite a relatively smaller capacity in terms of acreage, Pioneer places its focus on delivering the best possible quality. And with success! The company maximizes its harvest with a large percentage of A-size, premium quality potatoes.

However, every business has its challenges. Recognizing the need to stay competitive with its neighboring Skagit Valley growers, Pioneer Potatoes embraced optical grading technology as an essential step in that process.

Over the past few years, Pioneer Potatoes has faced the following challenges:

- Difficulty in finding and retaining workers throughout the entire season, making it difficult to maintain an efficient operation throughout the year.

Labor costs (salaries and overtime payments) continued to rise and competitors were investing in automation. This combination made it difficult to remain competitive with a higher per pound cost.

You can't compete on quality consistency with manual grading when everyone else is utilizing advanced grading technology. Customers started asking questions.

With manual sorting, it is very difficult to achieve the desired quality consistency because people, individually, and collectively, are inconsistent in defect detection especially across the course of a long day or season. Additionally, it is difficult for people to detect some of the complex defects that can be identified with technology.

When sorting by hand, inconsistent grading results in potatoes ending up in the wrong grades or to be classified as waste by mistake. This impacts our ability to maximize the value of each and every potato.

With manual grading, it was difficult to quickly change grading standards to address dynamic market and customer needs.

Why move from traditional sorting method to automation?

"Previously, our grading and packing process utilized the traditional industry methods including mechanical sizing and teams of people performing manual sorting. The mechanical sizer created the designated sizes, however, the accuracy could vary significantly depending on size and shape. All other grading functions were manual and relied on individuals to ensure correct sizes while also determining whether each potato was a reject, a lower grade or a premium grade. This approach placed a heavy responsibility on the workers, who did their best to achieve the desired results. However, it quickly became evident that automation, more consistent grading and increased throughput would be necessary to effectively compete in the market", tells Wylie Thulen of Pioneer Potatoes.

Main motivations for choosing Ellips|Elisam

"We decided to go with the Ellips-Elisam system based on a combination of factors. Firstly, there was a lot of buzz and talk about their solution within our industry. When everyone is excited about something, it grabs your attention. Secondly, our neighboring farms had already adopted this technology, and seeing it in action firsthand made a big impression. We had some prior exposure to similar Ellips systems used for apples and cherries, but witnessing its effectiveness with potatoes, especially when they were just a stone's throw away from our facility, made it more convincing. Seeing its success nearby made us believe it could work just as well for our operation. Last, but not least, John Albert also played a major role. He is a good salesperson, knows what he is talking about and he's local. He grew up 20 minutes from our place. He knows the valley, and that's a huge advantage."

Monumental cost savings by reducing the workforce by 50%.

"Potato grading technology is also interesting for smaller potato farms. There are a lot of reasons why we did it. The cost savings alone were huge for us. We managed to cut our workforce in half; we can now operate our entire line with just 12 people. It's bittersweet for a family business to reduce manpower, but from a business perspective, staying competitive requires careful calculation. In our case, the state of Washington raised wages and overtime payments, making it tough to afford and retain a large workforce. Reliance on manual labor also posed several risks. For example, we were dependent on finding and retaining sufficient staff every year. Based on labor reductions alone, we'll justify our investment in 4 to 5 years. In addition to labor savings, we have increased our capacity, improved our product quality and enhanced our ability to address our customers' specific needs."

Improved product quality and consistency gives you complete control

"Consistency in quality means everything to us. This technology has significantly boosted the reliability and consistency of our grading results. The Ellips grading system doesn't take sick days or get tired; it runs continuously according to the settings you've chosen. You can rely on its grading capabilities to identify product issues accurately and consistently, ensuring uniformity in our produce boxes. This consistency is fantastic for our customers because they always know what they're getting. Previously, we'd started losing some of our workforce toward the end of the season which made it difficult to maintain the quality of our product. Now, we have full control with just 12 people. We could actually operate with an even smaller staff, however, we occasionally require the additional staff for other projects."

Powerful defect detection that's fit individual needs

"The Ellips technology is fantastic for many reasons. One of the coolest things is its flexibility. When we got it, I didn't realize how much we could customize it based on our specific needs. It comes with a bunch of ready-to-use options, but the real magic is how adaptable it is. You can tweak it to suit your different potato varieties, fields and products. It's like having a solution that can be perfectly tailored for each batch. Instead of relying on someone's eyes to spot defects, these cameras catch everything, every time. And, if you need to get rid of something super specific, like a tiny black dot, you can program it to do just that."

More freedom with throughput improvements

"We handle about 10,000 tons yearly, which is roughly 20 million pounds. Currently, our processing speed consistently is approximately 15 tons per hour, up from our previous 12 tons. We invested in a 6-lane machine, with 4 "active". This means that in the future, we could "activate" 2 additional lanes and ramp up to a minimum of 22 tons per hour. Increasing our processing speed would make things even easier. For instance, we could work fewer days in a week, maybe just four, or adjust our work hours from 8:00 AM to 3:00 PM instead of the usual 7:00 AM to 5:00 PM. We might not need to run the machine full-time; perhaps three days a week would suffice, leaving the other two for packing. This additional flexibility could facilitate more desirable work schedules for our family and employees. Generally, when people work less but maintain their income, they tend to be happier. That's something we're aiming for in the future."

Future

"The grading technology we have is truly impressive—no issues at all. I'm eagerly anticipating the integration of Artificial Intelligence (True-AI) into this system. True-AI will utilize input from growers like us in order to further enhance the system's capabilities. Even though our grading system works virtually flawlessly, we are excited to see what new capabilities and features Ellips will introduce through the use of its AI technology in 2024 and beyond."

For more information:

For more information:

John Albert

Ellips

Tel: +1(206)-915-4962

john.albert@ellips.com

Full Customer Story Pioneer Potatoes