“Bananas wouldn’t be available on store shelves around the world if it wasn’t for the pre-conditioning and ripening process via ethylene application,” says Greg Akins, President and CEO of Catalytic Generators. “The same holds true for nearly all mature field-grown tomatoes purchased in grocery stores.” In recent years, more and more retailers have witnessed the benefits of pre-conditioning and ripening of fruits. Not just bananas, but other fruits including avocados, pears, mangoes, papayas, peaches, plums, etc. are increasingly available pre-ripened.

Avocados being displayed next to other produce with the right side of the display being ripe & ready to eat.

Avocados being displayed next to other produce with the right side of the display being ripe & ready to eat.

Repeat customers and larger quantities

What drives the availability of pre-ripened fruits at the store level? “The major benefit of pre-conditioning, as seen in bananas in retail centers for years, is increased sales,” shared Akins. “It allows customers not only to buy for consumption on the day of purchase, but also for later in the week,” he added. “Research has also shown that retail centers which consistently provide ready-to-eat fruit have more repeat customers and customers will also purchase larger quantities.” Customer satisfaction and repeat sales are the biggest drivers of retailers’ shift to pre-conditioning over the years.

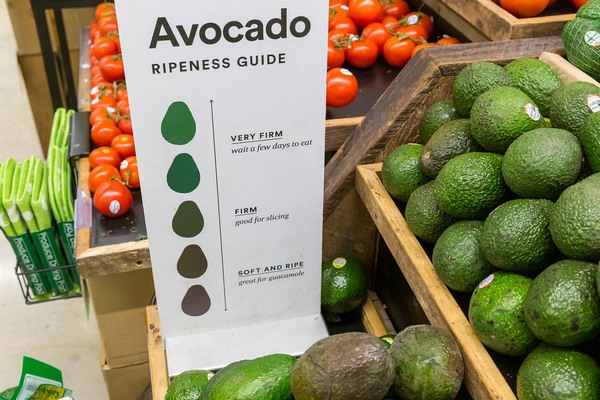

Sign educates consumers on the different stages of ripeness for avocados.

Sign educates consumers on the different stages of ripeness for avocados.

Opportunity for mangoes

Pre-conditioned fruit that is ripe and ready-to-eat changes the overall consumer experience in a positive way. Sometimes, these fruits are on separate displays in the store, making it easier for customers to identify. “We now see displays with ripe tomatoes and avocados for guacamole that can be made as soon as a customer gets home from the store,” said Katlynn Blackburn of Catalytic Generators. “Bananas or pears for instance can be purchased and packed into a kid’s lunch the next day for a delicious snack versus needing to be left out on the counter for a week with little or no taste,” she added. For some fruit items like bananas, 100 percent of available product has been pre-conditioned and ripened through ethylene before it reaches the consumer. However, there are also fruit varieties that show a significant opportunity for pre-conditioning and improving the consumer experience. Mangoes are an example. “There is great opportunity for more conditioning of mangoes to increase the availability of ripe fruit at retail.”

Ripe bananas and ripe pears on display. Consumers have a choice between ripe and not so ripe pears.

Ripe bananas and ripe pears on display. Consumers have a choice between ripe and not so ripe pears.

Warming process What is pre-conditioning exactly? “It basically is the ‘warming process’ after fruit has been held in cold storage,” explained Akins. “Conditioning refers to the application of ethylene, a natural plant hormone produced by fruit as it ripens.” Once the fruit has been placed in a ripening room and warmed to the right temperature, ethylene is applied to properly ripen the fruit. Catalytic Generators’ ethylene generators and Ethy-Gen® II Ripening Concentrate form a system that, when used as directed, produces concentrations ideal for conditioning a variety of fruit. The amount of ethylene concentration required depends on the type of fruit while the application time is determined by how mature the commodity is upon arrival. Each fruit variety responds differently. With the help of ethylene, many fruits will ripen in the same manner after harvest as they would on the plant as the external source of ethylene in the ripening room triggers the fruit to release its own ethylene. “For this reason, avocados, bananas and field-grown tomatoes are by far the most popular fruits to be ripened with ethylene, and there is ample opportunity for other fruits to take advantage of a ripening program.”

What is pre-conditioning exactly? “It basically is the ‘warming process’ after fruit has been held in cold storage,” explained Akins. “Conditioning refers to the application of ethylene, a natural plant hormone produced by fruit as it ripens.” Once the fruit has been placed in a ripening room and warmed to the right temperature, ethylene is applied to properly ripen the fruit. Catalytic Generators’ ethylene generators and Ethy-Gen® II Ripening Concentrate form a system that, when used as directed, produces concentrations ideal for conditioning a variety of fruit. The amount of ethylene concentration required depends on the type of fruit while the application time is determined by how mature the commodity is upon arrival. Each fruit variety responds differently. With the help of ethylene, many fruits will ripen in the same manner after harvest as they would on the plant as the external source of ethylene in the ripening room triggers the fruit to release its own ethylene. “For this reason, avocados, bananas and field-grown tomatoes are by far the most popular fruits to be ripened with ethylene, and there is ample opportunity for other fruits to take advantage of a ripening program.”

“Our generators all feature user-friendly operation and continuous, consistent ethylene production for superior ripening and degreening,” said Akins. They are a safe, easy, and convenient ethylene source.”

For a full list of fruits that can be ripened by ethylene, click here or contact: Greg Akins

Greg Akins

Catalytic Generators

Tel: +1 (757) 855-0191

[email protected]

www.catalyticgenerators.com