The management of rows in vineyards, orchards, and olive groves increasingly requires flexible, multifunctional technologies. In this context, BFM Italy's interchangeable inter-row attachments represent a practical development. A single inter-row arm can be configured for grass-cutting, tilling, or sub-row maintenance, allowing it to adapt to different seasonal, structural, and operational requirements.

© BFM SRL DI BERTOLUZZO FABRIZIO & C.Orchard plus kit

© BFM SRL DI BERTOLUZZO FABRIZIO & C.Orchard plus kit

Fabrizio Bertoluzzo, owner of a Piedmont-based company that has specialized in designing and constructing inter-row tillage machines for over 20 years, explains, "Today's farmers are looking for versatile machines. Our inter-row mowers have interchangeable attachments, so one frame can handle mowing, tilling, and under-row cleaning year-round. This reduces costs and increases operational efficiency. It is a modular system that caters to a farm's real needs, season after season."

|

|  © BFM SRL DI BERTOLUZZO FABRIZIO & C. © BFM SRL DI BERTOLUZZO FABRIZIO & C. |

Over the years, several innovations have been developed and are now sold on different continents, from Europe to North and South America. These innovations enable complete row management and align with the growing demand for environmental sustainability, efficiency, and reduced chemical inputs.

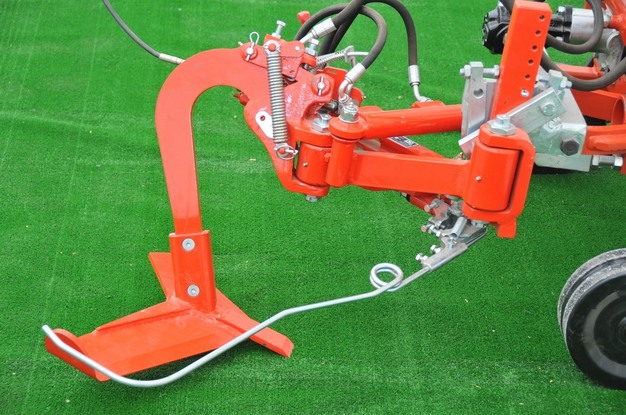

© BFM SRL DI BERTOLUZZO FABRIZIO & C.Lateral plow body

© BFM SRL DI BERTOLUZZO FABRIZIO & C.Lateral plow body

The main interchangeable BFM-branded accessories include:

- Egg-shaped shaft (A-130): Ideal for summer tillage, these toothed discs loosen the surface soil and create a spiral effect at a depth of 3 cm. This process eliminates weeds without causing soil leaching. It is adaptable to B1, B3, B4, DB11, and A-112.

- Spiral shaft (A-131): It is used for summer maintenance work in hilly areas. It moves soil to a depth of approximately 3/4 inch and lightly compacts the tilled soil. It is ideal for rocky soil and is compatible with B1, B3, B4, DB11, and A-112.

- Lateral plow body (A-111): Compatible with B3, DB11, DB12, AB9, B4, DB12 DUBLE, TPL, and basic tool frames.

- Tiller arm body: Available in various working sizes (A-112). It is adaptable to AB6 /DB12/AB9/ DB12duble)

- Stem and tamping shaft (A-121BIS): Disks affixed to the rotating shaft can be inverted to generate a stepping or tamping effect of approximately 7/8 centimeters while working the soil. (Adaptable to B1, B3, B4, DB11, and A-112.)

- Flat disc shaft (A-121): Designed for rocky soil, it uses discs to loosen the soil and form small clods, allowing the stump to breathe. (Works with B1, B3, B4, and A-112.)

- Narrow tilling header (A-122): Required when working in confined spaces with plants 40 cm apart. (Adaptable to B1, B3, B4, A-112, and DB11.)

- Orchard plus kit (A-132): A tool that provides greater reach than the DB12 in tree crops, such as citrus and hazelnut orchards. It has a 750 mm shaft, a lowered diverter and spool valve kit, and a uniformly designed cutting guard and chain kit.

- Weeder blade side body (A-119).

© BFM SRL DI BERTOLUZZO FABRIZIO & C.

© BFM SRL DI BERTOLUZZO FABRIZIO & C.

Thanks to interchangeable bodies and small-shaft systems, farmers can switch from shallow summer tillage to mechanical weeding with discs and even grass cutting with dedicated cutters. This optimizes time, costs, and operations. This sustainable approach replaces the use of chemical products with targeted mechanical work. The inter-row system is equipped with a hydraulic device with variable sensitivity that automatically retracts the tool when it comes into contact with a plant. This technology allows for safe operation, even in young plantations, and preserves the integrity of the plants.

For more information:

For more information:

BFM Italy

Via Santo Stefano Roero, 75

12043 Canale (Cuneo) - Italy

+39 0173 970453

[email protected]

bfmitaly.it