Whether it is cannabis or produce, every grower faces an ongoing battle against mold and similar threats. Cannabis in particular is vulnerable, since its humid cultivation environment and the physical structure of its flowers create an ideal breeding ground for many pathogens. Fruit, vegetables, and cut-flowers meanwhile, often perish in large quantities when they sit in containers or trucks for days before reaching their final destination.

Over the past two years, DDH has been working with an industrial plasma manufacturer to adapt cold plasma technology for controlled environment agriculture and shipping environments. The result is multiple products sold under the name Quantum Clear (QC).

Plasma

According to Travis Higginbotham of DDH , the original inventor had used plasma technology in other sectors and was looking for a partner to bring it to agriculture and horticulture. "We worked through two full years of design and testing so the equipment could function inside grow facilities, centralized HVAC systems, shipping trailers, and cold rooms," he said. The company has gathered data from USDA trials on several fruit crops, third party air quality testing on 50 different pathogens and volatile organic compounds such as ethylene, and pilot projects with large ornamental and cannabis operators.

© Due Diligence Horticulture

© Due Diligence Horticulture

The appeal of this approach, Travs points out, is that the plasma field does not create ozone, which is a concern with some existing plasma technology. The company holds UL and Carb certifications that verify the absence of ozone and confirm the units as safe plants and for human workplaces.

Preserving produce

The way it works is quite simple, practically speaking, at least. Air enters one side of the device, passes through a plasma field, and exits on the other side. In that field, gases become energized into a plasma state that generates reactive oxygen and nitrogen species, including hydroxyl radicals and hydrogen peroxide. These compounds interact with airborne pathogens and organic molecules. "The idea is to create a field in the environment that breaks down cell walls and alters the structure of certain compounds," Travis explains.

Fruit storage and shipping environments have been an early focus. "The combination of darkness, low temperatures, humidity, and tightly packed produce creates ideal conditions for mold," he says. "Lower air exchange and rising ethylene levels also push fruit toward faster ripening and softer tissue. USDA work with bananas, tomatoes, apples and strawberries showed that cold plasma treated shipments maintained quality and had almost no visible mold."

© Due Diligence Horticulture

© Due Diligence Horticulture

Due Diligence Horticulture has designed versions of the unit for shipping containers, coolers, HVAC systems, and cultivation spaces. This allows for flexibility throughout the supply chain, offers redundancy as well as centralized air handling treatment.

All of that implementation potential was also based on the attention the company put on safety, Travis remarks, not only for humans working in grow rooms, but for plants too."We pushed the tests hard and did not see negative effects," he says. Several data sets even suggested neutral to positive effects on yield and quality, though the company is still collecting more information. "We even doubled and tripled application capacity with no negative impact to cannabis flower pistils. The technology is gentle on the plant but destroys pathogens."

Cannabis

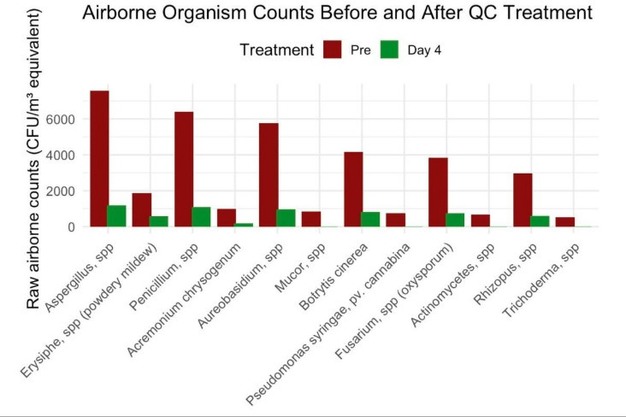

For cannabis growers, the interest centers on airborne pathogens linked to compliance failures, including aspergillus. "Operators also want to cut losses from powdery mildew or limit the cost and frequency of IPM interventions during flowering. Because plasma treatment can be applied from tissue culture rooms through to post harvest spaces, trials have looked at how the units behave across the cultivation cycle." The graph below shows results from a grower trial conducted in November 2025 where in just 4 days of use Aspergillus counts dropped 90%.

© Due Diligence Horticulture

© Due Diligence Horticulture

Vegetable and ornamental producers are also in the mix. Trials with Coastal Farms on shipping and with Metrolina Greenhouses on cooler storage have been completed, and more work is underway in Tissue Culture facilities in Central America and other controlled environments where air exchange is tightly managed.

© Due Diligence Horticulture

© Due Diligence Horticulture

Travis emphasized that installation is simple compared to systems that rely on chemical injection. "The units are standalone boxes designed for different voltages and room sizes. No subscription service is attached to the equipment, and the devices come with a standard warranty and optional extended coverage. DDH also offer financing to help growers secure their Quantum Clear cold plasma units."

© Due Diligence Horticulture

© Due Diligence Horticulture

Across the various studies, the company reports an average airborne pathogen reduction of 87.2% within under a week of use and higher reduction of 95%+ when units run continuously for up to a month."It is a practical tool for growers who want to not only control air quality but who also want to understand management of air quality better." he says. "The focus is getting the technology in growers hands through our trial program and building confidence that QC is the solution they have been waiting for."

Want to know more? Tune in on DDH webinar on December 10th at 10am PT. Click here to register.

For more information:

Due Diligence Horticulture

www.ddhort.com