Asparagus processing is facing a technological revolution: the classic horizontal peeling system, which has been the standard for decades, is increasingly being replaced by modern vertical peeling technology. The reason is obvious – quality, efficiency, and hygiene clearly favor the new process.

Why vertical peeling is gaining acceptance

While horizontal peeling technology often delivers uneven results due to the natural curvature of the spears and requires reworking, vertical peeling delivers a precise, even peel – regardless of diameter or shape. The rods are guided only at the head and processed precisely all around, without the risk of breakage or excessive waste. Especially in times of labor shortages, this means less manual work, consistently high quality, and significantly lower process costs.

© Hepro GmbH

© Hepro GmbH

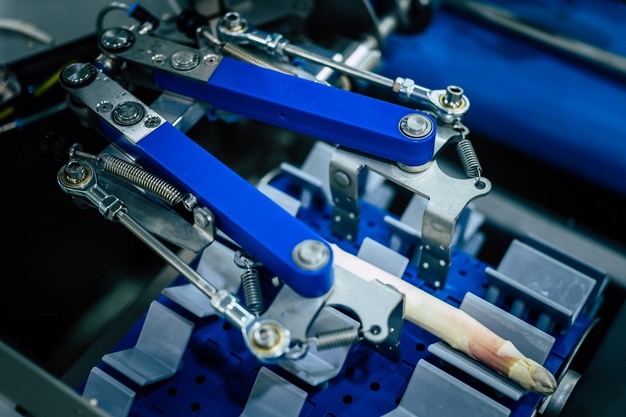

The latest generation of vertical peeling machines is equipped with XL grippers.

A leap forward in hygiene and ease of use

The current generation of vertical peeling machines impressively demonstrates how far development has come. Hygienic design, improved gripper technology, and optimized water flow have made cleaning much easier. In ECO mode, water consumption can be reduced by over 60 percent – a win for operating expenses and the environment.

Flexibility has also been noticeably increased: the new systems process a wide variety of stem diameters without readjustment and deliver results that are difficult to achieve even by hand.

© Hepro GmbH

© Hepro GmbH

The highest level of engineering – made by HEPRO

"Our team has given its all in recent years to take vertical peeling to a new level," emphasizes Christoph Wolter (pictured above), Managing Director of HEPRO GmbH. "With the new XL technology, we have achieved a milestone: a combination of precision, stability, and flexibility that has never been seen before in asparagus peeling. These machines represent the highest level of engineering excellence – and they show what is possible when passion meets technology."

© Hepro GmbH

© Hepro GmbH

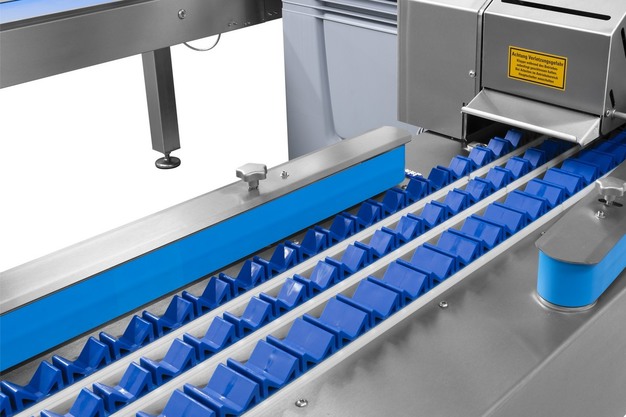

New XL feed conveyor

The new generation at expoSE in Karlsruhe

The experiences of the 2025 season confirm the trend – more and more companies are opting for the vertical process. Demand for the new XL machines is high, and many producers are already making the switch. "Anyone who wants to see for themselves should take the opportunity at expoSE in Karlsruhe. There, interested parties can experience live on the HSM 6000 XL how easy and efficient modern asparagus peeling is today – and why it is worth switching to the new technology. Because one thing is certain: those who invest now are betting on the future instead of the past."

Visit the company at expoSE 2025: Hall 1 / D02

For more information:

www.hepro-gmbh.de