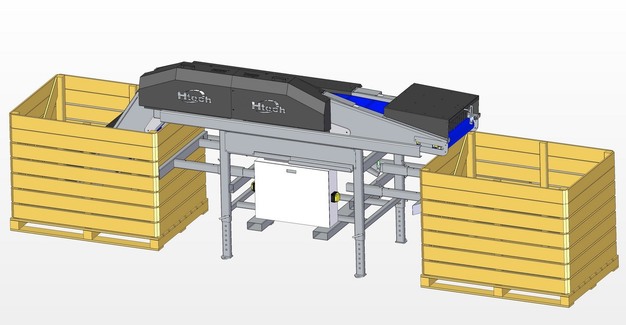

Being able to adjust the drop height at the end of your sorting line, when boxes are filled, is a reliable way to reduce damage to the products, says Tomáš Zdráhal, area sales manager of Czech machinery manufacturer Htech cz s.r.o."Our DBF (Dynamic Box Filling) machine is an advanced solution for gently and evenly filling bins with respect to produce delicacy. It features hydraulically adjustable arms and integrated sensors that ensure minimal drop height throughout the entire filling process. The filling technology continuously maintains the lowest possible drop height. Products are fed into a movable conveyor that gently lowers them into the box. When the crop is detected by a photosensor, the conveyor automatically raises to prevent damage."

© Htech cz s.r.o.

© Htech cz s.r.o.

"With a capacity of 40–50 boxes per hour, the DBF prioritizes both product-friendliness and operational efficiency. Boxes are partially filled in layers by nodding the filling belt and shifting it within the bin, ensuring even distribution and gentle handling."

© Htech cz s.r.o.

© Htech cz s.r.o.

According to Zdráhal, the dual-box system ensures there is no downtime, as operators can replace one of the boxes while another box is being filled. "The DBF filler is perfectly suited for facilities handling large volumes of product and can be positioned downstream from high-capacity equipment, such as optical sorters or radial graders. Thanks to its dual-box system, the operation remains uninterrupted, while one side is being filled, the operator has ample time to replace the other box. If needed, the machine can be equipped with a weighing unit, allowing it to fill boxes to a pre-set target weight. Alternatively, the weighing system can be used solely for weight control purposes."

© Htech cz s.r.o.

© Htech cz s.r.o.

Zdráhal states that the machine's ability to adjust the filling arm ensures that the drop height is minimized: "What makes our machine unique is the sensors that are located at the end of the filling arm, which allow the machine to automatically adjust to the product level, ensuring even distribution and minimizing drop height. Long fingers on the conveyor guide the product and prevent uncontrolled falls from the belt. The DBF is designed for robust products such as potatoes, carrots, and onions."

© Htech cz s.r.o.

© Htech cz s.r.o.

Htech also provides support after the machine is installed, with their own technicians. "All our machines can be equipped with modems for remote control, significantly simplifying online support. By working with high-quality suppliers, we try to minimize any potential negative impact on our machines. However, should an issue arise, we have a highly flexible and responsive service team ready to assist. Since we are based in the Czech Republic, practically in the heart of Europe, we're able to cover a wide area with our own technicians. Our flexibility is further enhanced by an additional service center in Poland. Beyond our direct reach, we maintain a network of partner service providers. In our central warehouse, we stock over 80% of spare parts for our machines," Zdráhal concludes.

For more information:

For more information:

Tomáš Zdráhal

Htech cz s.r.o.

Tel: +420 724 117 977

[email protected]

www.htech.cz