The demand for pre-processed, ultra-fresh fruit and vegetable products has noticeably increased in Germany over the past few years, especially in the catering sector. However, product specifications regarding packaging units are evolving differently, reports Henrik Rolf, Co-Managing Director of Köckerling, based in Delbrück (Paderborn region). "Bakeries and chain stores are particularly fond of smaller packaging sizes, such as 250-gram units. To reduce effort in the kitchen and work more resource-efficiently, system caterers and large consumers, on the other hand, specifically ask for large containers of between 1 and 2.5 kilograms or even larger. Thus, interestingly, the fresh-cut market seems to move in two opposite directions."

Köckerling was founded in 1947 and has developed over the past decades from a family-run potato farm into a renowned supplier of various fresh-cut products. The company's focus is primarily on supplying the food service and food industry within a 250-300km radius. Rolf: "Currently, the retail sector represents about 10% of our business activities. However, we are striving to expand this segment in the coming years, not least because Corona has shown us how important a second, stable source of revenue is."

The Köckerling management team, with Henrik Wolf (l) and Johannes Köckerling.

The range of fresh convenience products in German retail lags compared to neighboring European countries. "However, one must not forget that frozen fruit and vegetables are firmly rooted in our culture. This means that many consumers, especially older ones, still prefer frozen food over fresh convenience. This is slowly changing as younger consumers grow up with these products. It is also important to note that not just the selection of convenience goods has significantly improved, but the quality as well. There is a tendency to use fewer preservatives, which benefits the quality of the goods. Where I see particular potential for optimization in retail is in the area of packaging. We keep finding that plastic packaging deters consumers. However, one must always look at both sides, because in the end, food safety must not be compromised. We also pay close attention to the recyclability of the respective plastic packaging. The less composite material we use, the better. Accordingly, we try to use mono-plastic if possible."

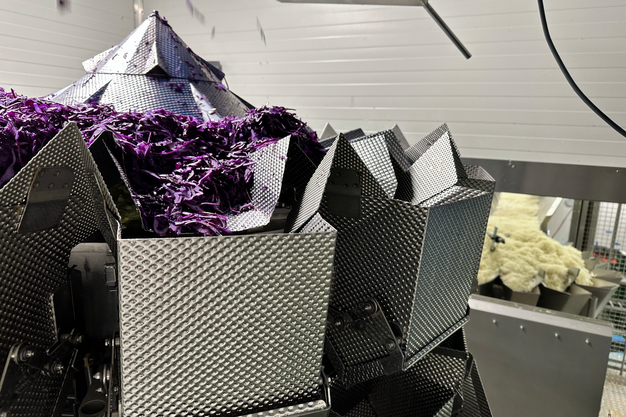

Multihead weigher.

Highs and lows within raw material procurement

Regarding potatoes, our raw material needs can largely be met with produce from our fields, Rolf continues. Otherwise, the raw materials needed for processing are sourced from suppliers both near and far. "As for procurement, we have some difficult years behind us. 2018 was marked by extreme drought and corresponding shortages. Then came Covid, with extreme highs and lows. Post-Covid, we got the war in Ukraine and the energy crisis. The associated uncertainty, especially regarding storage products like potatoes, onions, and carrots, makes it increasingly difficult to give a concrete market assessment and determine fixed prices. To counteract shortages and be able to offer everything at that time, we strive to find double suppliers for each article. Nevertheless, weather extremes repeatedly lead to scarcities, especially with Spanish products."

View of the packaging lines.

Expansion of own brand and capacities

To be well-prepared for the future, Köckerling will continue to invest, Rolf reveals. "At the beginning of the Covid crisis, we launched our brand 'Fresh in Love' for the retail sector. We would like to expand this product line in the coming years. Additionally, we have invested in our premises and plant technology in the past two years. We want to continue this strategy of process optimization so that we can produce faster and, above all, higher quality products."

Drying belt.

Images: Köckerling GmbH & Co. KG

For more information:

Henrik Rolf

Köckerling GmbH & Co. KG

33129 Delbrück

Im Brinkort 6

Tel. 0 29 44 - 97 97 70

Fax 0 29 44 - 97 97 729

info@köckerling-frische.de

www.köckerling-frische.de