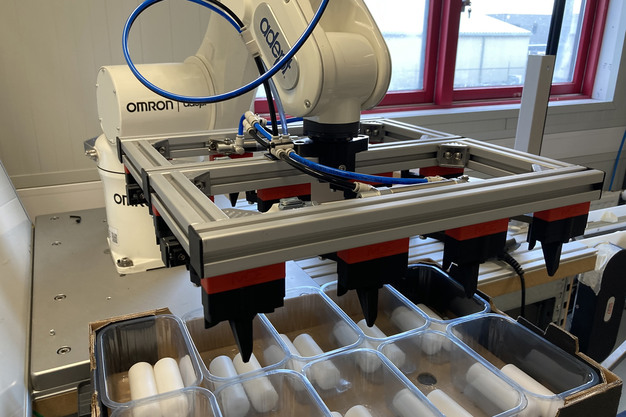

Three years ago, the Dutch company MDE Automation took its first steps into the fresh produce sector with a completely new line for optimizing chicory processing at Reijnpack. That made it clear to MDE Automation founder Edwin Denissen that there were more automation opportunities in that sector. The latest development is a gripper that can pick up plastic punnets of fruit and vegetables from boxes and place them at any desired location. It can also case-pack punnets coming off the packaging line.

MDE Automation expects this newly developed gripper to provide soft fruit, grape, and mushroom packers with a fully automatic solution. "It's a game changer for efficiently loading crates at the end of packaging lines. The entire process, from unpacking from the box to packing, is fully automated. The boxes are located using Vision technology," Edwin begins.

The gripper can be used for both open and closed punnets and grips the tray's edge. "The challenge was firmly gripping a 500g punnet without damaging it. We opted for a non-vacuum solution. The gripper also doesn't go into the punnet, thus avoiding damaging the product or top seal."

The video below shows the gripper in a demo environment:

"Over the past few years, I visited several packing plants and was often amazed at how much work is still done manually. The sector naturally has to deal with seasonal influences, but there's genuinely still plenty to automate. People are literally placing cucumbers in a sealing machine, and on the other side, someone packs the sealed cucumbers into a box. There's nothing simpler to automate," Edwin explains.

"I was also unfamiliar with repacking fruit and vegetables, where all labels are replaced. We've also devised a solution for that where the entire pallet is automatically re-labeled. At Reijnpack, we've demonstrated what's possible with automation. The new robot line saves 50% on labor. Above all, continuity can be guaranteed because three lines are pounding away."

Edwin sees many opportunities to further automate the fresh produce sector. "We specialize in automating production processes, with an emphasis on technology, efficiency, precision, and safety. The world of industrial automation is changing rapidly," he says. "What's already possible with Artificial Intelligence (AI) is unprecedented. For tech enthusiasts like us who focus purely on technology, it's a true playground."

"As an official Omron Solutions Partner, we always have access to the latest machine controlling, vision, and robotics technology. With the help of these, we can quickly add value for our customers. That can be for machines or production lines, but we also support fellow machine builders. We help find and create innovative products or machine solutions. There's so much work, there's actually no competition," Edwin concludes.

For more information:

For more information:

Edwin Denissen

MDE Automation

48 Slabbecoornweg

4691 RZ, Tholen, NL

info@mde-automation.nl

www.mde-automation.nl